HDPE Plastic Bottle Blow Molding Machine Corrugated Moulding

-

High Light

eva plastic bottle blow molding machines shuangli

,eva plastic bottle blow molding machines SLD-75

,ISO eva plastic bottle blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity10L

-

StationSingle

-

ProductPlastic Corrugated Bottle

-

Layer1-4 Layer

-

Die Head1-4 Head

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLD-75

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

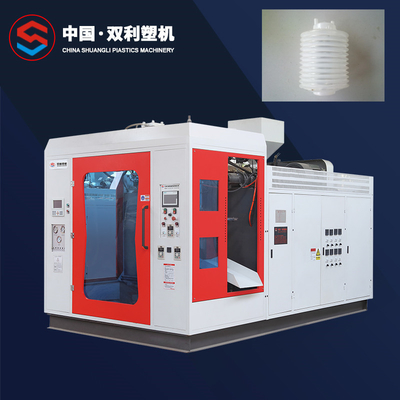

HDPE Plastic Bottle Blow Molding Machine Corrugated Moulding

D Type High Speed Single Station Plastic Bottle Blow Molding Machine with IML for Plastic Corrugated Bottle

SLD series:

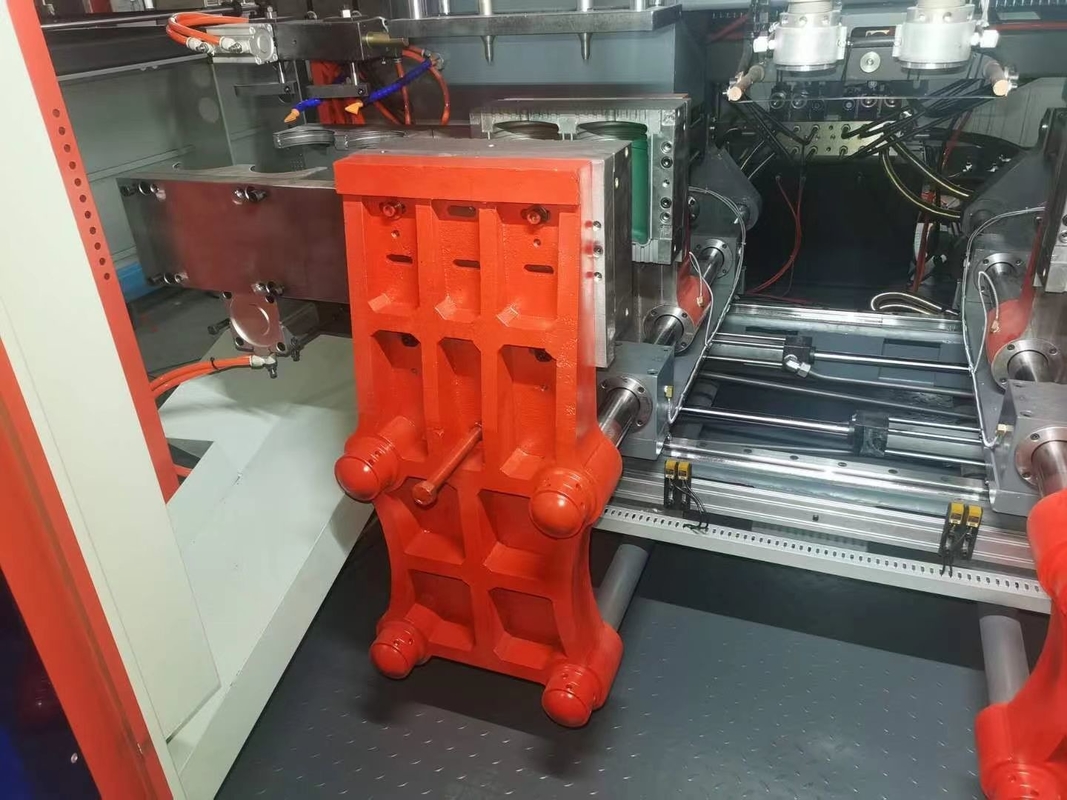

1: this machine is suitable for the production of 200ML 10L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speedF aster, run more smoothly.

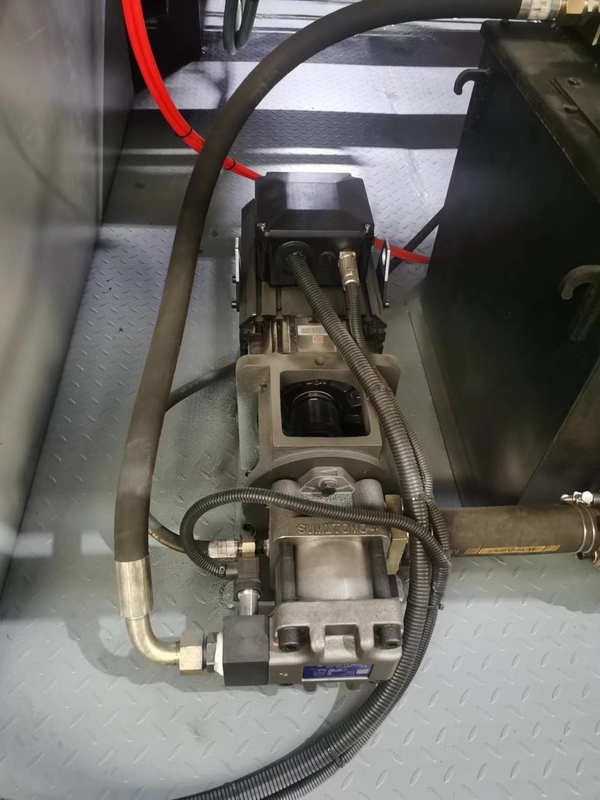

2: die opening and closing system: specially designed for Heng lock mould mechanism using a high pressure mode locking, locking plate stress in the centre of the template, clamping force, open. All parts of the machine is made by advanced numerical control equipment with high precision. And equipped with imported hydraulic, pneumatic and electrical parts of famous brand, it has stable equipment performance and simple handling.ot up modeThe rigid lock template, even if the ultra wide die is also fitted. die head system: all the use of 38CRMOALA and other materials, the precision machining and heat treatment.

3: Our machine is using German famous brand for servo variable-speed pump drive, which makes the machine high efficient and high energy saving. In addition, we are using good quality Austrian control panel to ensure the convenience in operation and advanced technology.

The extrusion die head design system, it is based on accurate, multilayer coextrusion die head adopts unique heart-shaped channel, including all types of die head can increase the level of design, extrusion volume is prolific, the weight of the product is stable, which is to ensure uniform plasticizing. Die headsystem equipped with advanced gear box, running smoothly, which is long and durable, die in each channel is reasonable distributed, the flow can be adjusted, parison wall thickness is evenly produced, color change can be more quickly and easily.

| SPECIFICATION | SLD-75 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 10 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 600 |

| MACHINE DIMENSION (LxWxH ) | MM | 4300x2400x2200 |

| TOTAL WEIGHT | TON | 7.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-530 |

| PLATEN SIZE(WxH) | MM | 320x350 |

| MAX MOULD SIZE(WxH) | MM | 400x350 |

| MOLD THICKNESS | MM | 225-320 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 75 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 95 |

| BARREL HEATING POWER | KW | 20 |

| NUMBER OF HEATING ZONE | ZONE | 4 |

| EXTRUDER MOTOR RATED POWER | KW | 22 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 8 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 200 |

| POWER | ||

| MAX DRIVE POWER | KW | 24 |

| TOTAL POWER | KW | 62 |

| FAN POWER OF SCREW | KW | 3.6 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.5 |

| AVERAGE ENERGY CONSUMPTION | KW | 22 |

![]()

![]()