2 Head Plastic Bottle Blow Molding Machine D Type 15l PP Bottle Blowing

-

High Light

SHUANGLI 4 heads plastic bottle blow molding machines

,SHUANGLI 4 heads plastic bottle blow molding machine

,4 heads plastic bottle blow molding machine SHUANGLI

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity15L

-

StationSingle

-

ProductGarden Watering Can

-

Machine TypeD Type-tie Bar

-

Die Heads2 Heads

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLD-80

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

2 Head Plastic Bottle Blow Molding Machine D Type 15l PP Bottle Blowing

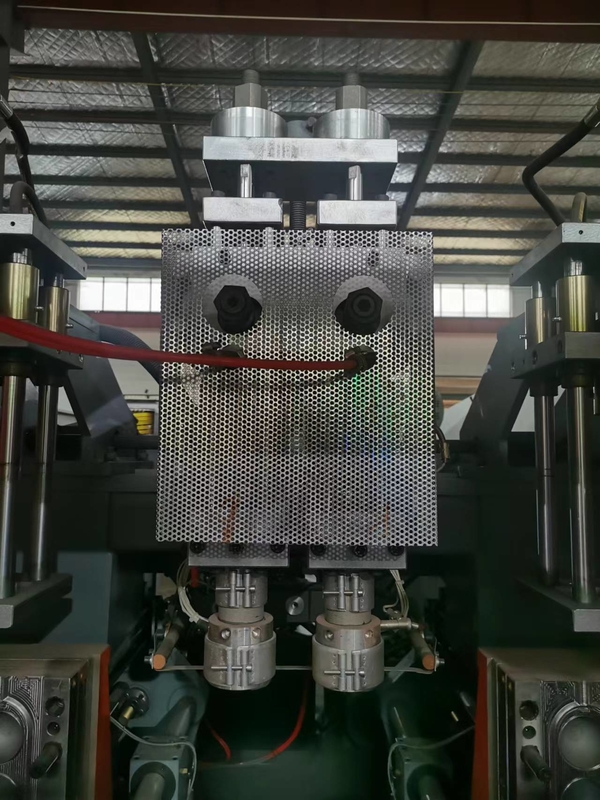

D Type High Speed Single Station Plastic Bottle Blow Molding Machine with IML for 2 Heads Plastic Garden Watering Can

SLD series:

1: this machine is suitable for the production of 200ML 15L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speed faster, run more smoothly. and consists of 4-guide-pillar structure and 3-plate pulling structure, which can not only hold super-wide and super-long molds but also provides enough locking force. It can produce plastic bottles of various shapes such as milk bottles, cosmetic bottles, jerry can, ocean balls and etc.

2: die head system: all the use of 38CRMOALA and other materials, the precision machining and heat treatment. And automatic flying side device: in addition to the overflow device can accurately remove the product of the residual material, and with a straight push type in addition to the overflow device and a rotary knife type in addition to overflow device, the real realizationAutomatic equipment without manual operation.

3: Machine can keep normal service life only under good conditions.

1).Abide by all notes in this manual strictly.

2). Pay attention to surface cleaning.

3). Check all fasten conponents. Tighten them if they are found loose.

4). Keep enough lubricating of moving surfaces and choose correct lubrication.

50Rated pressures of all action oil cylinders are 14Mpa. Be careful during operation.

| SPECIFICATION | SLD-80 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 15 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 600 |

| MACHINE DIMENSION (LxWxH ) | MM | 4600x2600x2200 |

| TOTAL WEIGHT | TON | 8T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 68 |

| PLATEN OPENING STROKE | MM | 300-650 |

| PLATEN SIZE(WxH) | MM | 350x400 |

| MAX MOULD SIZE(WxH) | MM | 450x400 |

| MOLD THICKNESS | MM | 305-350 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 80 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 120 |

| BARREL HEATING POWER | KW | 24 |

| NUMBER OF HEATING ZONE | ZONE | 4 |

| EXTRUDER MOTOR RATED POWER | KW | 30 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 8 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 160 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 280 |

| POWER | ||

| MAX DRIVE POWER | KW | 30 |

| TOTAL POWER | KW | 82 |

| FAN POWER OF SCREW | KW | 3.6 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.5 |

| AVERAGE ENERGY CONSUMPTION | KW | 28 |

![]()