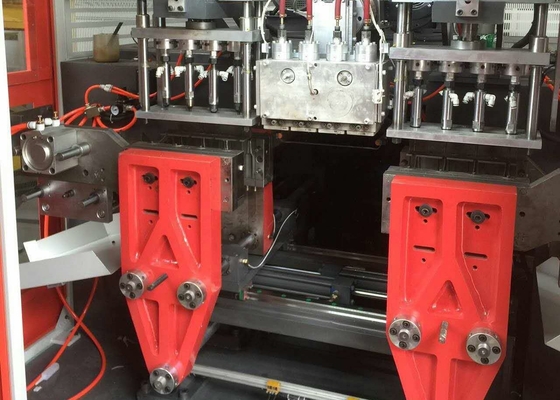

K Series Tie Bar High Speed Double Station 4 Die Head High Speed Blow Molding Machine For Plastic Sea Ball

SLBK series

1: the mold head mechanism: the use of the split type of the head, not channeling material, more uniform, more uniform, plating processing, not accumulating material, the material is more smooth.application areas: food, medicine, petroleum, chemical, chemical, automotive, tools, toys and other industries.

2. Check the oil temperature. Several hours after the machine starts running, the oil temperature ranges from 30℃-50℃. If the oil temperature exceeds 60℃, please stop the machine and cool it down.

3 Check if the system pressure is normal.

4. Check the oil amount of the central lubrication system. If necessary, please fill lubricant.

5. Check if there is trouble in the safety light screen of the clamping area (refer to the user’s manual for details). In case there is, please don’t start the machine.

| SPECIFICATION | SLBK-55 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3400x2200x2200 |

| TOTAL WEIGHT | TON | 5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-400 |

| PLATEN SIZE(WxH) | MM | 260X330 |

| MAX MOULD SIZE(WxH) | MM | 300x330 |

| MOLD THICKNESS | MM | 125-220 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 11 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 32 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 13 |

![]()