2l CO Extrusion Blow Molding Machine Tie Bar Glue Bottle Equipment

-

High Light

2l CO extrusion blow molding machine

,tie bar CO extrusion blow molding machine

,glue bottle extrusion blow molding equipment

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity2L

-

StationDouble Or Single

-

ProductPlastic Glue Bottle

-

SpeedHigh Speed

-

TypeK Series Tie Bar

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBK-55

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

2l CO Extrusion Blow Molding Machine Tie Bar Glue Bottle Equipment

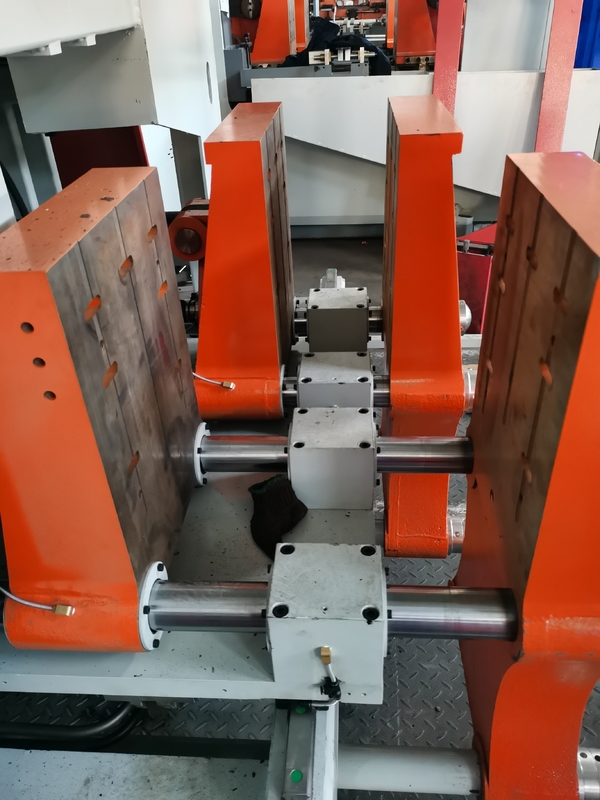

Double Station K Series Tie Bar High Speed 2 Die Head High Speed Blow Molding Machine For Plastic Glue Bottle

1: the mold head mechanism: the use of the split type of the head, not channeling material, more uniform, more uniform, plating processing, not accumulating material, the material is more smooth.

2: plasticizing system: frequency conversion motor Hardened reducer with high quality nitride barrel screw, variable frequency speed control, energy efficient and stable yield. Production Volume:2ml~5LMulti layers: Co-Extrusion 1 Layer

3: electronic control system: the use of PLC man- machine interface, all parameters set, modify, retrieval can be seen as the operation, the system runs stable, accurate positioningIndeed. can be equipped with automatic overflow device: supporting cutting device and pull the end device, automatic operation, save labor.

4. After the installation and handover of the blow molding machine finish, trial may be carried out. The steps of trial are as followed.

(1 Set initially the temperature at various heating zone according to the requirement of the molding process of the plastic used. When the actual temperature is higher than the set temperature, the corresponding fan should be immediately started to cool it down.

(2 Close the safety door, turn the Emergency Button out, and activate the oil pump. Please observe if the rotating direction of either of the two motors is in accordance with the direction indicated. If it isn’t, please exchange at random any two cables in the power supply (operate only when it is powered off. Don’t change the cable connection in the power distribution box);

| SPECIFICATION | SLBK-55 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3400x2200x2200 |

| TOTAL WEIGHT | TON | 5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-400 |

| PLATEN SIZE(WxH) | MM | 260X330 |

| MAX MOULD SIZE(WxH) | MM | 300x330 |

| MOLD THICKNESS | MM | 125-220 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 11 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 32 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 13 |

![]()