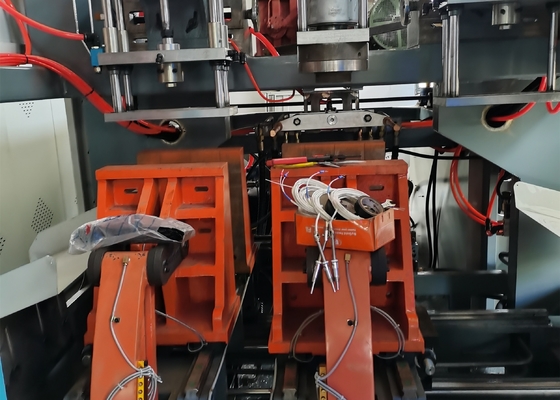

U series High Speed 1 Layer Double Station 1 Die head Blow Molding Machine for Plastic Kitchenware.

SLBU series:

1: this machine is suitable for the production of 200ML -5L plastic hollow products, the use of curved elbow lock system, low energy consumption,

the center of the lock, the lock force, speed faster, run more smoothly.Servo Hydraulic System includes Servo Head Lifting, Servo Die Head,

Servo Parison Control System, Servo Blow Pin, Servo Clamping Unit and Servo Carriage

2: Slow frame down pressure: When fully automatic, when the current mode shifting action hits the slow down mode shift proximity switch,

The hydraulic system pressure is converted from the lower frame down pressure to the lower frame down pressure until the pressure is stopped

when the end of the lower die is approached to the switch. The lower shift mode impact is controlled by the lower frame lower pressure and the

buffered one-way throttle valve at the rear end of the cylinder. When there is a shock sound in the lower shift mode, the lower frame lower

pressure is reset and the pressure is lowered. Second, the adjusting screw on the one-way throttle valve is screwed clockwise inward, and is

adjusted until the lower shifting mold has no impact sound. Pay attention to safety when adjusting the lower die throttle valve. The down frame

pressure is also the pressure of the mold shift under manual operation. If the manual lower mold does not move, just set the lower frame pressure

to high, but in the fully automatic operation, the lower frame pressure should be set low. The general pressure analog quantity is set between 100

and 350.

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()

![]()