8 Cavities 18kw Plastic Bottle Molding Machine Plastic Ball 4 Cavity Blow Moulding

-

High Light

8 cavities plastic bottle molding machine

,18kw plastic bottle molding machine

,plastic ball 4 cavity blow moulding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity2L

-

StationDouble

-

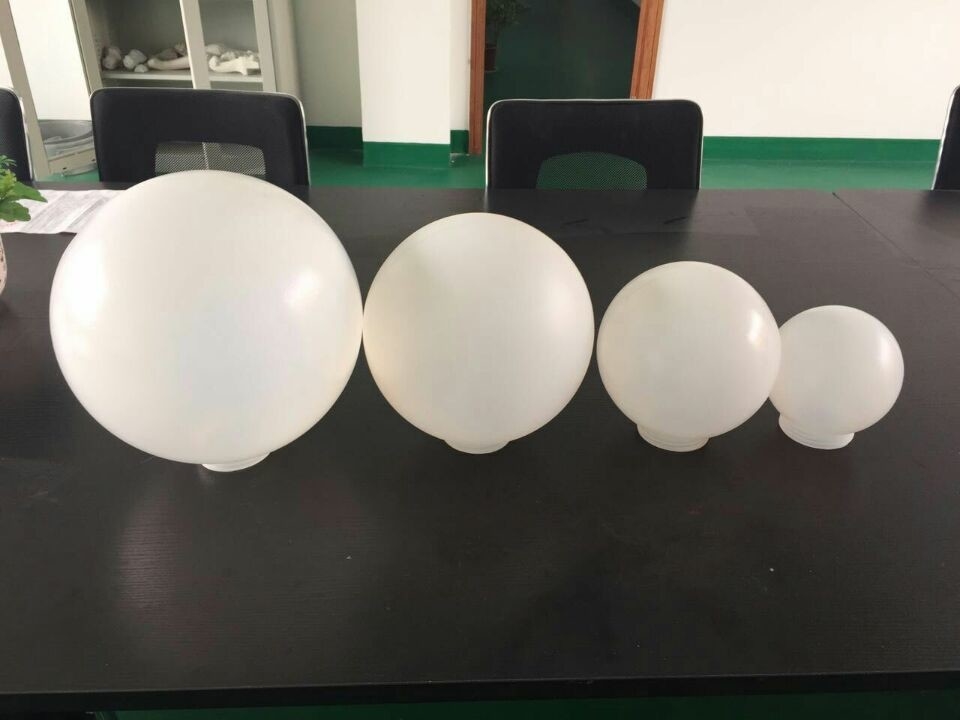

ProductPlastic Light Ball

-

SpeedHigh Speed

-

TypeK Series Tie Bar

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBK-55

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

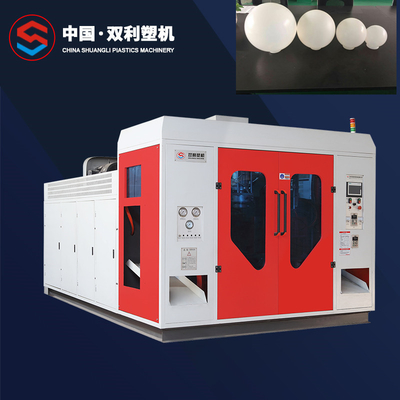

8 Cavities 18kw Plastic Bottle Molding Machine Plastic Ball 4 Cavity Blow Moulding

Automatic Tie Bar High Speed 2 Die Head Blow Molding Machine For Plastic Light Ball

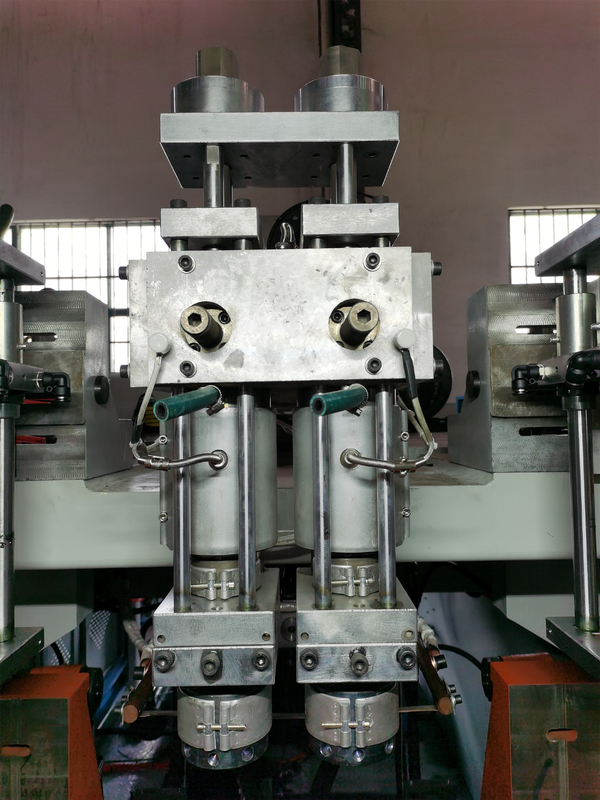

1: the mold head mechanism: the use of the split type of the head, not channeling material, more uniform, more uniform, plating processing, not accumulating material, the material is more smooth.

2: plasticizing system: frequency conversion motor Hardened reducer with high quality nitride barrel screw, variable frequency speed control, energy efficient and stable yield.

3: electronic control system: the use of PLC man- machine interface, all parameters set, modify, retrieval can be seen as the operation, the system runs stable, accurate positioningIndeed.

4: application areas: food, medicine, petroleum, chemical, chemical, automotive, tools, toys and other industries.

5: can be equipped with automatic overflow device: supporting cutting device and pull the end device, automatic operation, save labor.

K series extrusion blow-molding machine is the most budget-friendly product. Although after years of technological upgrades, it still occupies a position in the market with high-level performance. The mold locking system of K series

consists of 4-guide-pillar structure and 3-plate pulling structure, which can not only hold super-wide and super-long molds but also provides enough locking force. It can produce plastic bottles of various shapes such as milk bottles, cosmetic bottles, jerry can, ocean balls and etc.

✓Single/Double Station

✓Single/Double/Triple/Quadruple..8 Head

✓Production Volume:2ml~2L

✓Multi layers: Co-Extrusion 1-4 Layers

✓Multi cavities: 1~8 cavities

✓Designed for the PE/PP/PETG/PVC/Co-Extrusion material

| SPECIFICATION | SLBK-55 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3400x2200x2200 |

| TOTAL WEIGHT | TON | 5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-400 |

| PLATEN SIZE(WxH) | MM | 260X330 |

| MAX MOULD SIZE(WxH) | MM | 300x330 |

| MOLD THICKNESS | MM | 125-220 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 11 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 32 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 13 |

![]()