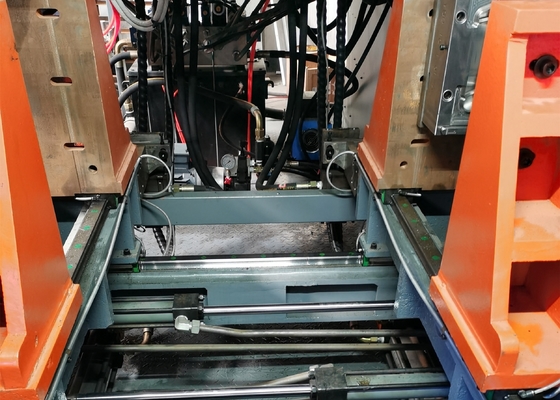

High Speed 1 Layer Double Station 6 Die head Blow Molding Machine for Plastic Medical Bottle

SLBU series:

1: this machine is suitable for the production of 200M-5L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speedF aster, run more smoothly.

2: Plastic Medical Bottle Machine Setting.

Upper bias: When the current value is higher than the set value and exceeds the upper deviation, the heating stops working. If there is a cooling fan, the cooling fan starts to cool.

Lower bias: When the current value is lower than the set value and lower than the lower deviation, the heating starts to work. If the cooling fan is working, it stops working.

Lower limit: When the current value is lower than the set value and reaches the lower limit value, an alarm will be issued. At this time, the operator should check the heating condition of the alarm, such as whether the heater, thermocouple, etc. work normally.

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()

![]()