1000 Bph 5l Single Station Blow Molding Machine Servo Plastic

-

High Light

1000 bph single station blow molding machine

,5l single station blow molding machine

,servo plastic blowing machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

ProductPlastic Automobile Parts

-

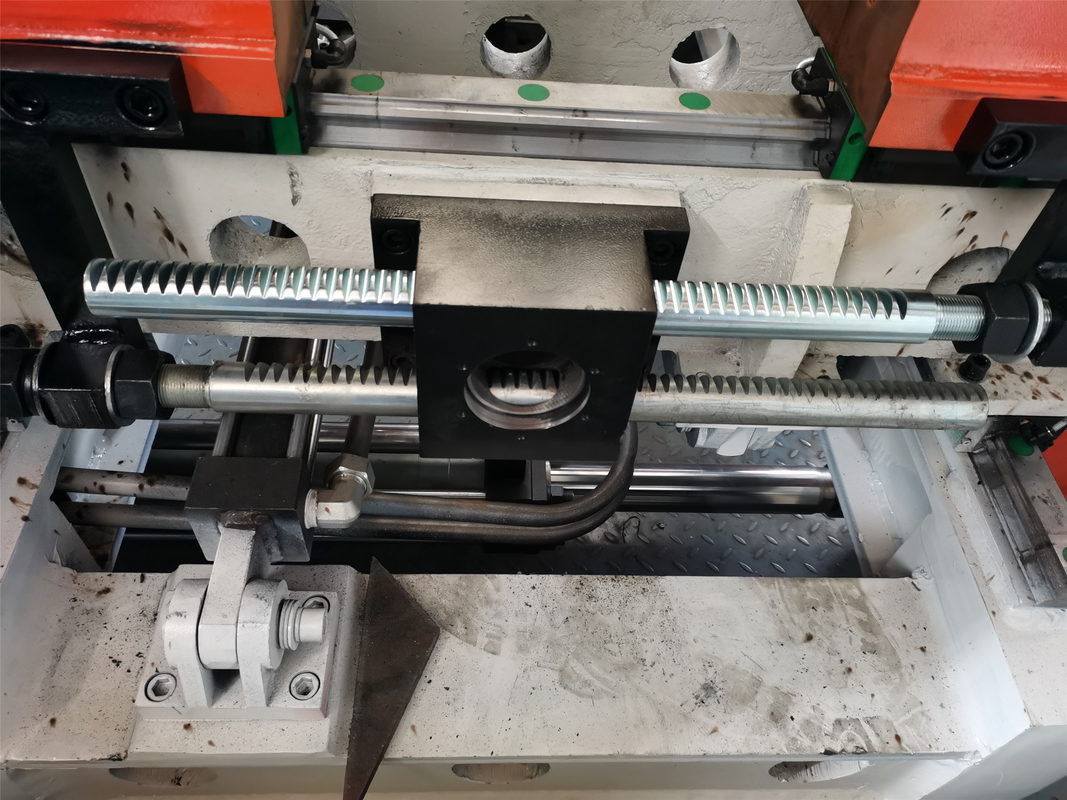

Clamping TypeToggle Type-U Type

-

StationDouble Or Single

-

Die Head1 Head

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

1000 Bph 5l Single Station Blow Molding Machine Servo Plastic

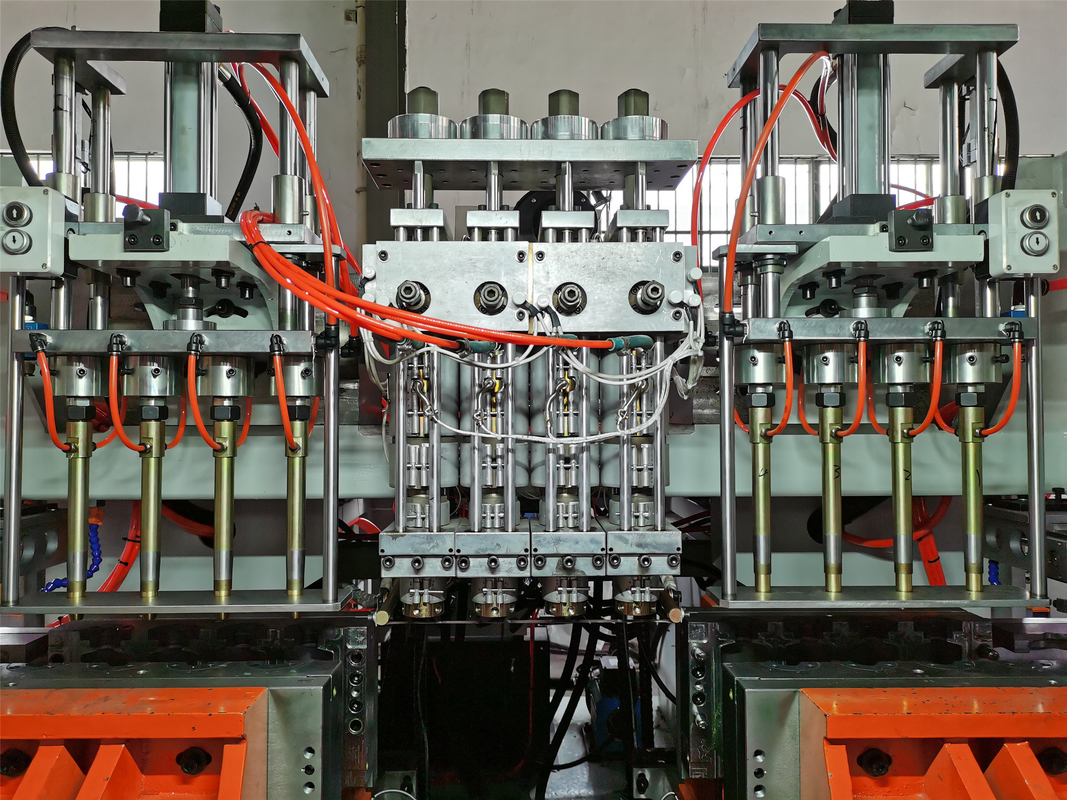

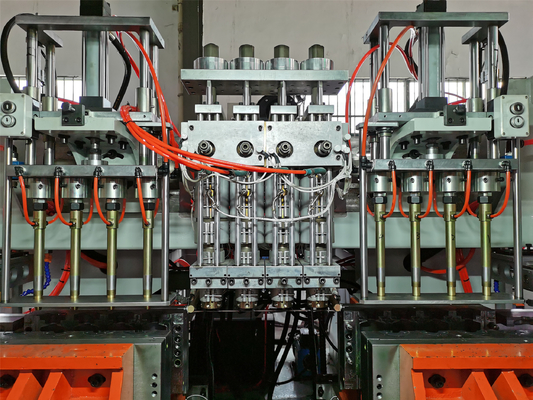

High Speed 1 Layer Double Station 1 Die head Blow Molding Machine for Plastic Automobile Parts

SLBU series:

1: this machine is suitable for the production of 5L plastic hollow products, Servo Parison Control System, Servo Blow Pin, Servo Clamping Unit and Servo Carriage

2: Temperature parameter setting screen:

There are a total of one to four (or more) temperature control. For each parameter setting, just click on the number, a numeric input keyboard will pop up automatically, click the value to be set, and then press the enter key to confirm the value. With storage.

3.Set value: This value is set according to the raw materials used.

Current value: It means that the current temperature transmitted by the thermocouple is transmitted to the temperature control module, and then the temperature control module transmits to the PLC and finally to the value displayed on the touch screen.

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()

![]()