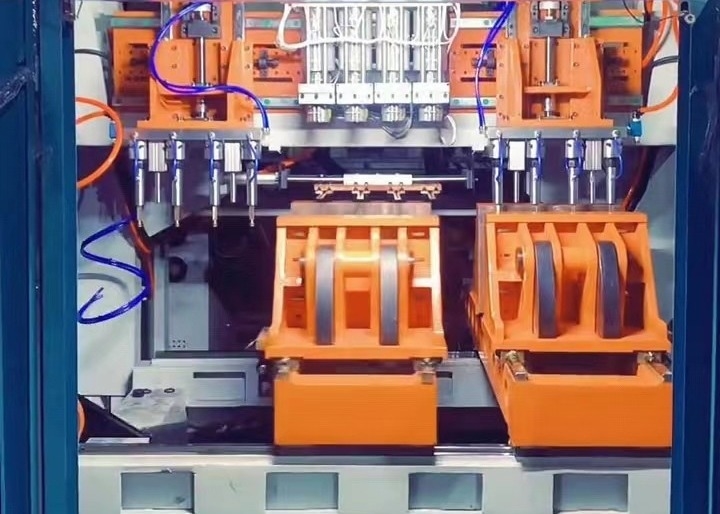

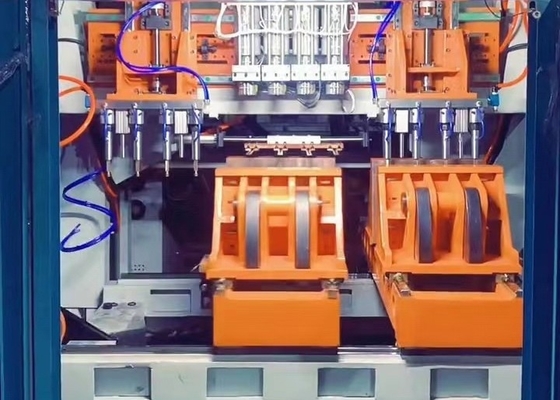

20l Fully Electric Blow Molding Machine 1 Head PP Double Station

-

High Light

20l Fully Electric Blow Molding Machine

,1 head Fully Electric Blow Molding Machine

,PP double station blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity20L

-

ProductPlastic Chemical Bottle

-

Machine TypeFully Electric

-

StationDouble Station

-

Die Head1-8 Heads

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBUD-90

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

20l Fully Electric Blow Molding Machine 1 Head PP Double Station

Fully Electric Double Station Blow Molding Machine for Plastic Chemical Bottle SLBUD-90

SLBUD series:

1. this machine is suitable for the production of 200ML- 20L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speedF aster, run more smoothly.

With toggle balance clamping system for high accuracy and excellent clamping force.

2:.die opening and closing system: specially designed for Heng lock mould mechanism using a high pressure mode locking, locking plate stress in the centre of the template, clamping force, openThe rigid lock template, even if the ultra wide die is also fitted.

3. die head system: all the use of 38CRMOALA and other materiais, the precision machining and heat treatment.

4.Full Electric Blow Molding Machine

Electronic Clamping Frame Adopts the Eccentric Gear Structure with Lower Energy Consumption and Quciker Response.

Linear Rail Electronic Blowing Pin Greatly Increases the Accuracy.

Servo Electronic Head Lifting with High Accuracy and Smooth Performance.

Optimized Die Head Flow Path for Fast Color Changing.

Electronic Carriage adopts Rack and Gear Structure to Ensure the Accuracy, Lower Energy Consumption and Quicker Response.

| SPECIFICATION | SLBUD-90 | ||

| MATERIAL | PE,PP,EVA,ABS,PS | ||

| MAX CONTAINER CAPACITY | L | 20 | |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 | |

| OUPUT(DRY CYCLE) | PC/HR | 220x2 | |

| MACHINE DIMENSION (LxWxH ) | MM | 5200x3200x2400 | |

| TOTAL WEIGHT | TON | 15T | |

| CLAMPING UNIT | |||

| CLAMPING FORCE | KN | 160 | |

| PLATEN OPENING STROKE | MM | 350-750 | |

| PLATEN SIZE(WxH) | MM | 600x600 | |

| MAX MOULD SIZE(WxH) | MM | 600x580 | |

| MOLD THICKNESS | MM | 360-420 | |

| EXTRUDER UNIT | |||

| SCREW DIAMETER | MM | 90 | |

| SCREW L/D RATIO | L/D | 25 | |

| MELTING CAPACITY | KG/HR | 140 | |

| BARREL HEATING POWER | KW | 30 | |

| NUMBER OF HEATING ZONE | ZONE | 5 | |

|

KW | 45 | |

| DIE HEAD | |||

| NUMBER OF DIE HEATING ZONE | ZONE | 3-12 | |

| POWER OF DIE HEATING | KW | 10-30 | |

| CENTER DISTANCE OF DOUBLE DIE | MM | 250 | |

| CENTER DISTANCE OF THREE DIE | MM | 130 | |

| CENTER DISTANCE OF FOUR DIE | MM | 100 | |

| CENTER DISTANCE OF SIX DIE | MM | 80 | |

| MAX DIE-PIN DIAMETER | MM | 280 | |

| POWER | |||

| MAX DRIVE POWER | KW | 50 | |

| TOTAL POWER | KW | 110 | |

| FAN POWER OF SCREW | KW | 4 | |

| AIR PRESSURE | MPA | 0.8-1 | |

| AIR CONSUMPTION | M3/MIN | 0.6 | |

| AVERAGE ENERGY CONSUMPTION | KW | 35 | |