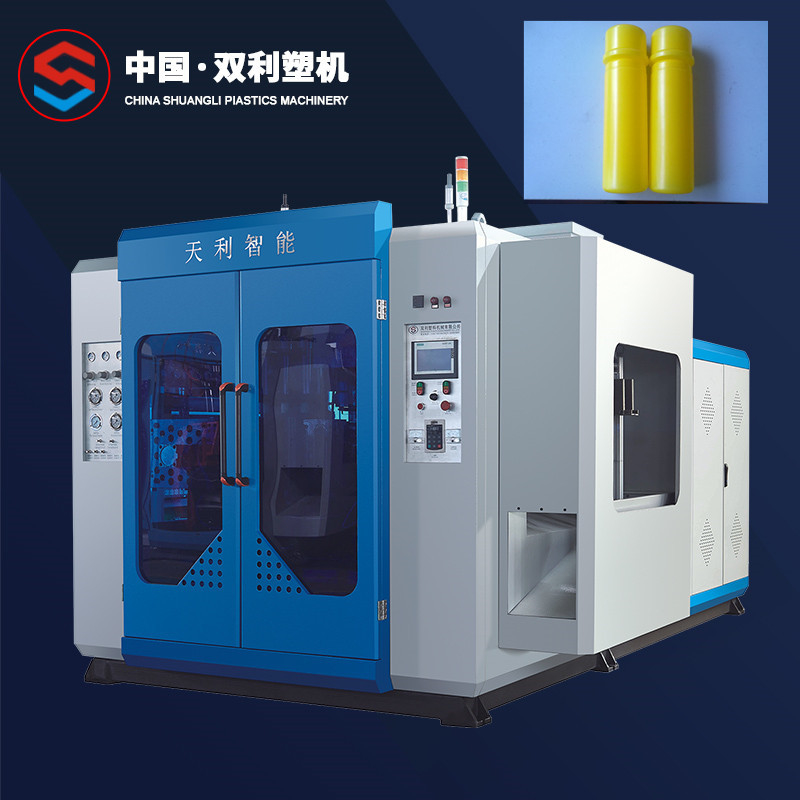

Plastic Tube HDPE Blow Moulding Machine High Speed 1000bph Plastic Blowing

-

High Light

SLBU-65 tube hdpe blow moulding machine

,tube hdpe blow moulding machine SLBU-65

,tube hdpe blow moulding machines SLBU-65

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

ProductPlastic Tube Accessory

-

Clamping TypeToggle Type -U Type

-

Layer1 Layer

-

StationDouble Or Single

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Plastic Tube HDPE Blow Moulding Machine High Speed 1000bph Plastic Blowing

HDPE High Speed 1 Layer Automatic Extrusion Blow Molding Machine for Plastic Tube Accessory

SLBU series:

1. When the fully automatic blow molding machine is being repaired, press the touch screen fault repair button to ensure safe maintenance. If you need to manually observe the action of each individual cavity, please pay attention to the position of the robot. At the same time, be sure to clear the role of separate buttons to ensure that the malfunction caused unnecessary trouble.

2. When the high-low pressure air source switch is turned on, it must be operated slowly to prevent the gas source from flowing too fast. The dirt is blown into the solenoid valve. At the same time, the exhaust valve is opened for 30 seconds to ensure the air is clean.

3. After the normal operation of fully automatic blow molding machine, any part of the body do not reach into the machine to avoid injury to the robot. If the machine has abnormal noise, it can be observed after deceleration.

4: this machine is suitable for the production of 200ML- 10L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speed faster, run more smoothly.

5: hydraulic system: full hydraulic double proportional hydraulic control, equipped with imported famous brand hydraulic valve and oil pump, stable, reliable. And equipped with imported hydraulic, pneumatic and electrical parts of famous brand, it has stable equipment performance and simple handling.

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()