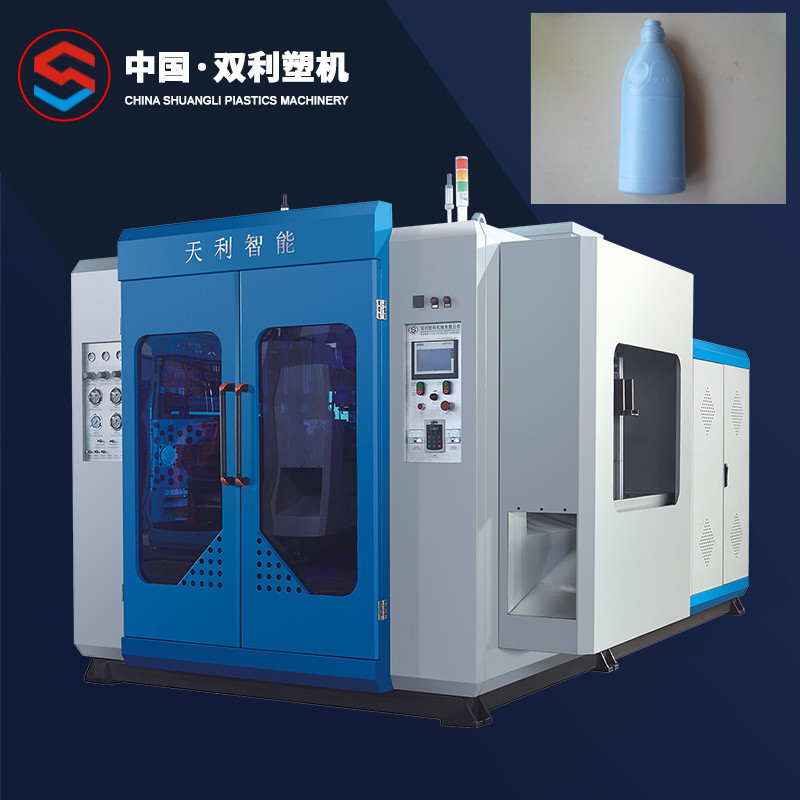

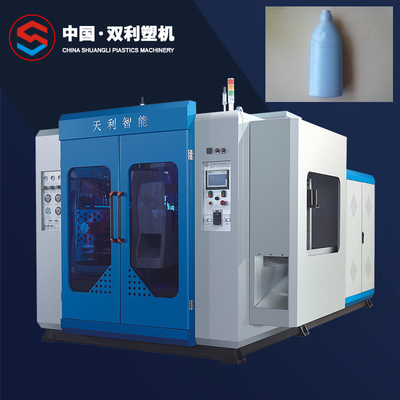

HDPE 4 Layers Small Bottle Blowing Machine , Servo Bottle Blower Machine

-

High Light

4 layers small PET bottle blowing machine

,HDPE small PET bottle blowing machine

,servo PET bottle blower machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity10L

-

StationDouble

-

Clamping TypeToggle Struction

-

ProductSmall Detergent Bottles

-

Layer1-4 Layers

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-80

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

HDPE 4 Layers Small Bottle Blowing Machine , Servo Bottle Blower Machine

HDPE Double Station Extrusion Blow Molding Machine for Plastic Small Detergent Bottles

SLBU series:

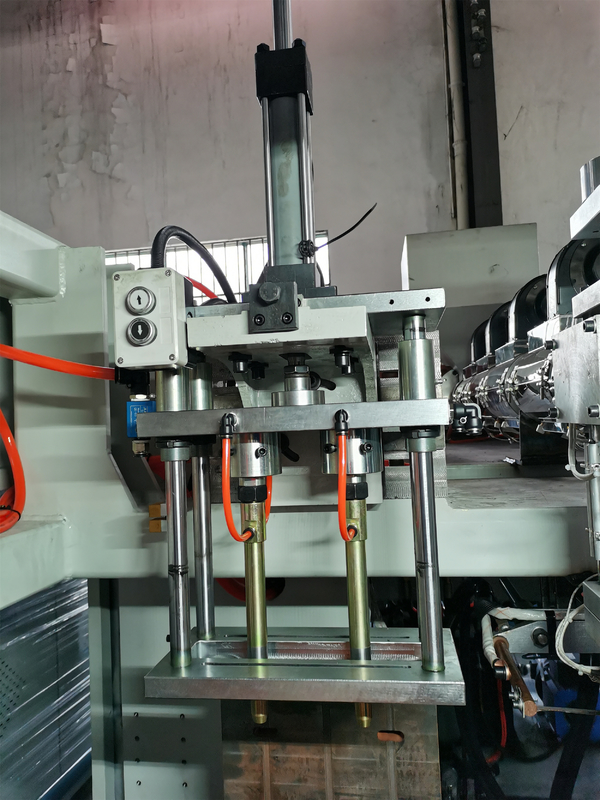

1 Automatic flying side device: in addition to the overflow device can accurately remove the product of the residual material, and with a straight push type in addition to the overflow device and a rotary knife type in addition to overflow device, the real realizationAutomatic equipment without manual operation.

2,Servo Hydraulic System includes Servo Head Lifting, Servo Die Head, Servo Parison Control System, Servo Blow Pin, Servo Clamping Unit and Servo Carriage

3.Blow Molding Machinery and Equipment daily check and maintenance:

(1)If the clamping linear position sensor is sensitive and reliable.

(2)Check the heating part to see if the fixation is firm, if there is short circuit.

(3)Check the oil pump and pipe of the motor is leaking.

(4)Check the oil level in the oil tank.

(5)Check the circulation of the cooling water.

| SPECIFICATION | SLBU-80 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 10 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 950x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4600x2600x2600 |

| TOTAL WEIGHT | TON | 7.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 86 |

| PLATEN OPENING STROKE | MM | 300-600 |

| PLATEN SIZE(WxH) | MM | 450x450 |

| MAX MOULD SIZE(WxH) | MM | 500x450 |

| MOLD THICKNESS | MM | 305-400 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 80 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 120 |

| BARREL HEATING POWER | KW | 20 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 30 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 160 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 260 |

| POWER | ||

| MAX DRIVE POWER | KW | 35 |

| TOTAL POWER | KW | 82 |

| FAN POWER OF SCREW | KW | 3.2 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.5 |

| AVERAGE ENERGY CONSUMPTION | KW | 22 |

![]()