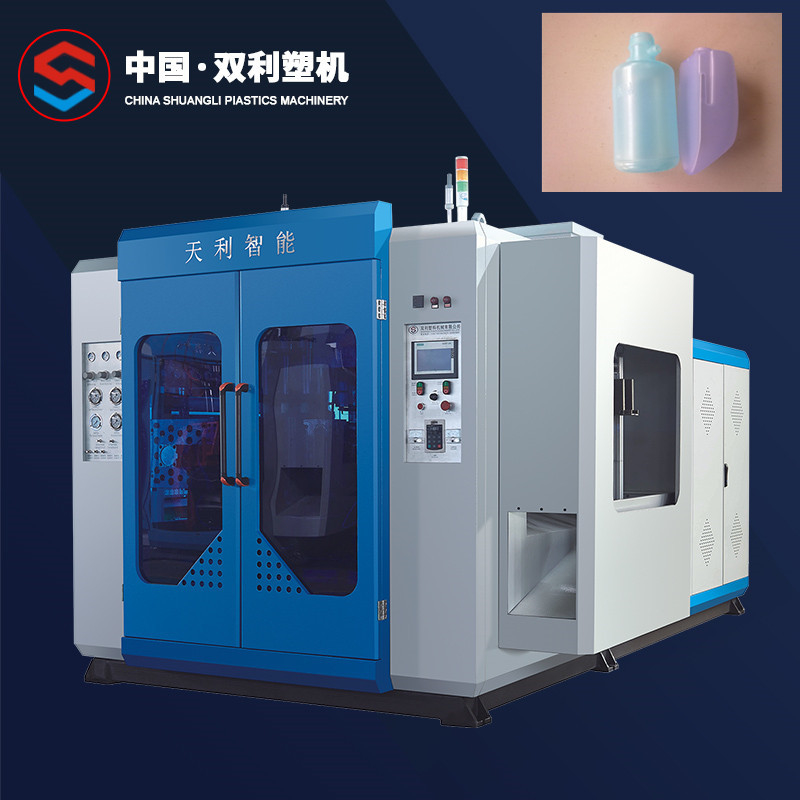

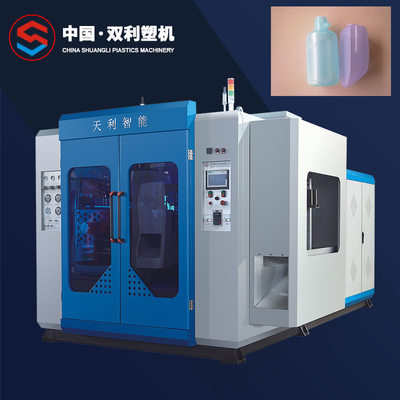

Cosmetics Box HDPE Blow Moulding Machine Double Station 3 Layers 10L

-

High Light

SHUANGLI cosmetics box hdpe blow moulding machines

,SHUANGLI cosmetics box hdpe blow moulding machine

,CE cosmetics box hdpe blow moulding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity10L

-

ProductSmall Plastic Cosmetics Box

-

Clamping TypeToggle Type -U Type

-

Layer1-3 Layers

-

StationDouble Or Single

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-80

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Cosmetics Box HDPE Blow Moulding Machine Double Station 3 Layers 10L

HDPE Double Station Extrusion Blow Molding Machine for Small Plastic Cosmetics Box

SLBU series:

1: die head system: all the use of 38CRMOALA and other materials, the precision machining and heat treatment.

2 hydraulic system: full hydraulic double proportional hydraulic control, equipped with imported famous brand hydraulic valve and oil pump, stable, reliable.

3: automatic flying side device: in addition to the overflow device can accurately remove the product of the residual material, and with a straight push type in addition to the overflow device and a rotary knife type in addition to overflow device, the real realizationAutomatic equipment without manual operation.

4 The function of PLC and PC in blow molding machine

(1) Switch quantity, simulation quantity:the related logical control about temperature, pressure, flow control, oil pump, valve.

(2) The timing function: Blow and exhaust gas,the time knocking out some action , how much time delay, all controlled through the inside timer.

(3) Technical features: some rotation need to know the position, we can know it by sending pulse encoder.

| SPECIFICATION | SLBU-80 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 10 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 950x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4600x2600x2600 |

| TOTAL WEIGHT | TON | 7.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 86 |

| PLATEN OPENING STROKE | MM | 300-600 |

| PLATEN SIZE(WxH) | MM | 450x450 |

| MAX MOULD SIZE(WxH) | MM | 500x450 |

| MOLD THICKNESS | MM | 305-400 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 80 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 120 |

| BARREL HEATING POWER | KW | 20 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 30 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 160 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 260 |

| POWER | ||

| MAX DRIVE POWER | KW | 35 |

| TOTAL POWER | KW | 82 |

| FAN POWER OF SCREW | KW | 3.2 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.5 |

| AVERAGE ENERGY CONSUMPTION | KW | 22 |

![]()