2 Head Continuous Extrusion Blow Molding 2 Layer 2l Double Station

-

High Light

2 head continuous extrusion blow molding

,2 layer continuous extrusion blow molding

,2l double station blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity2L

-

ProductPlastic Beverage Containers

-

Clamping TypeTie Bar Type

-

Layer2 Layers

-

StationDouble

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBK-55

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

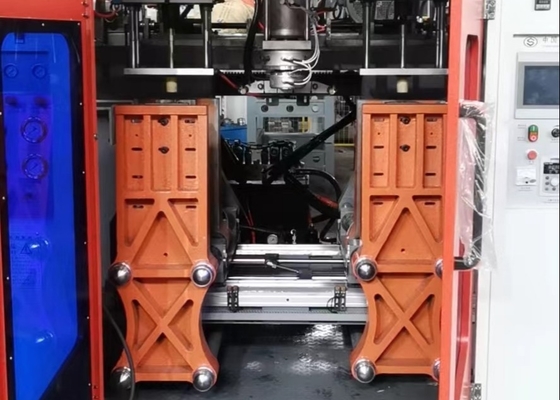

2 Head Continuous Extrusion Blow Molding 2 Layer 2l Double Station

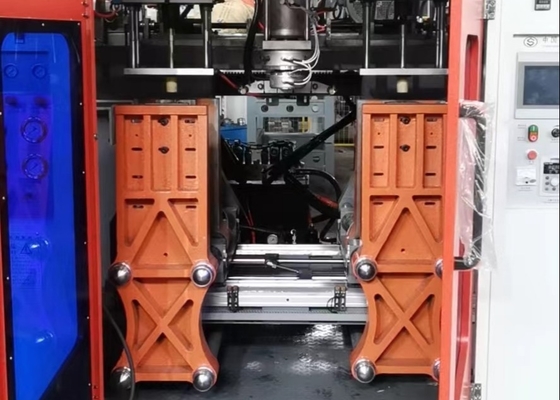

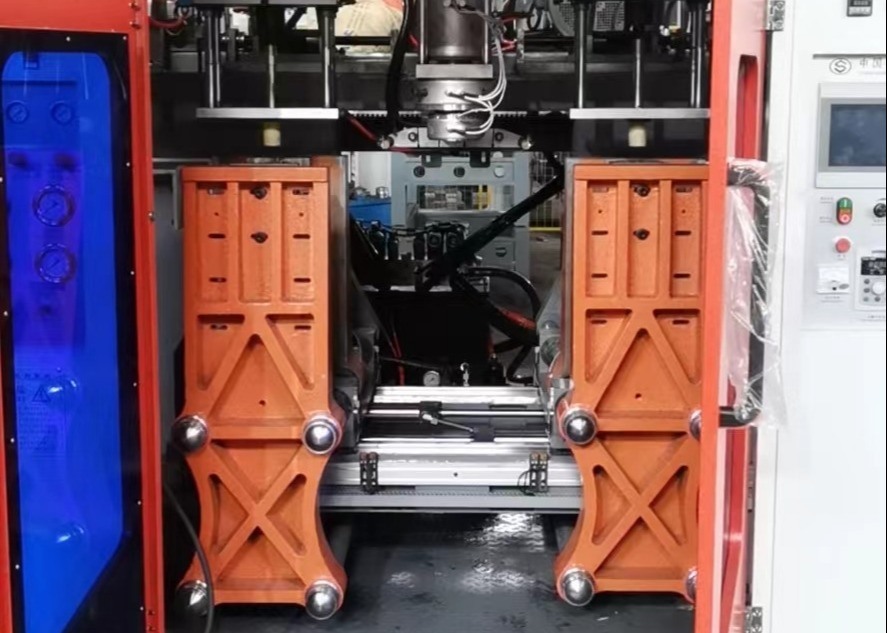

Double Station K series Tie Bar High Speed 2 Layers 2 Die Heads Blow Molding Machine for Plastic Beverage Containers

SLBK series

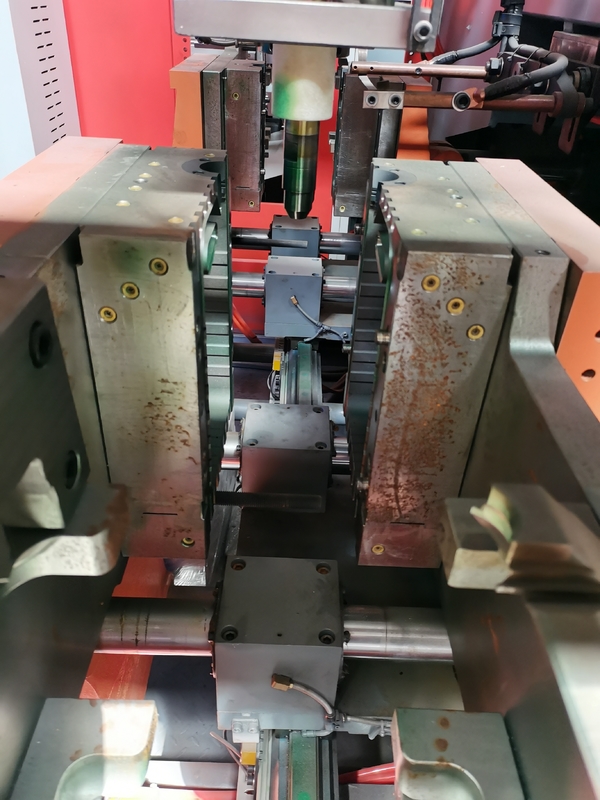

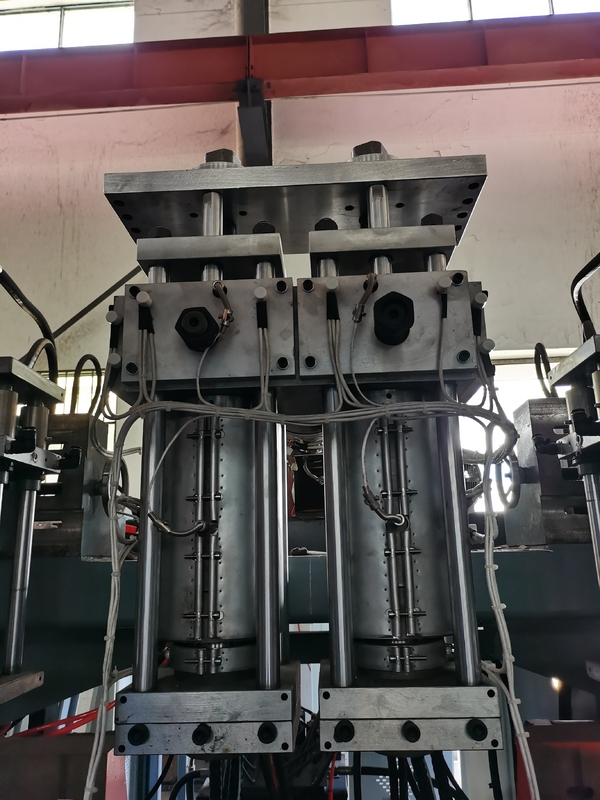

1: the mold head mechanism: the use of the split type of the head, not channeling material, more uniform, more uniform, plating processing, not accumulating material, the material is more smooth.

2: plasticizing system: frequency conversion motor Hardened reducer with high quality nitride barrel screw, variable frequency speed control, energy efficient and stable yield.with tie-bar design clamping unit and PLC Techmation.

3: Properly adjust the position of the opening and closing mold proximity switch to make the closing mode smooth.

Install the die and the needle that match the mold. When the manual needle is slow, adjust the center of the blow head to the center of the mold, and make the blow head just hit the die at the bottom dead center.

Adjust the cutter so that the cutting blade is 20~30mm from the end face of the die.

Turn on the cooling water and compressed air such as the mold and the needle, and the machine will be fully automatic for about half an hour, then enter the actual test run.

| SPECIFICATION | SLBK-55 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3400x2200x2200 |

| TOTAL WEIGHT | TON | 5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-400 |

| PLATEN SIZE(WxH) | MM | 260X330 |

| MAX MOULD SIZE(WxH) | MM | 300x330 |

| MOLD THICKNESS | MM | 125-220 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 11 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 32 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 13 |

![]()