3 Head Continuous Extrusion Blow Molding Cosmetic Bottle 2l Automatic

-

High Light

3 head Continuous Extrusion Blow Molding

,cosmetic bottle Continuous Extrusion Blow Molding

,2l automatic extrusion blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity2L

-

ProductPlastic Cosmetics Bottle

-

Clamping TypeK Series Tie Bar

-

Layer2 Layers

-

StationDouble Or Single

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBK-55

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

3 Head Continuous Extrusion Blow Molding Cosmetic Bottle 2l Automatic

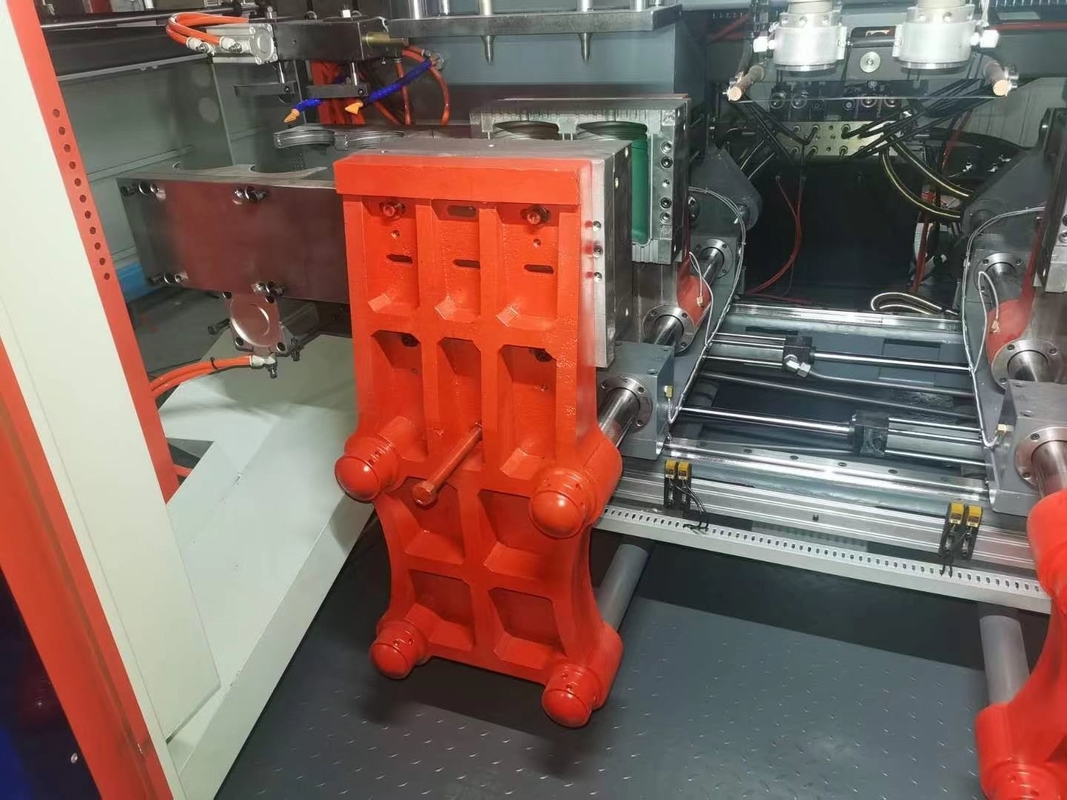

K series Tie Bar High Speed 2 Layers Double Station 3 Die head Blow Molding Machine for Plastic Cosmetics Bottle

SLBK series

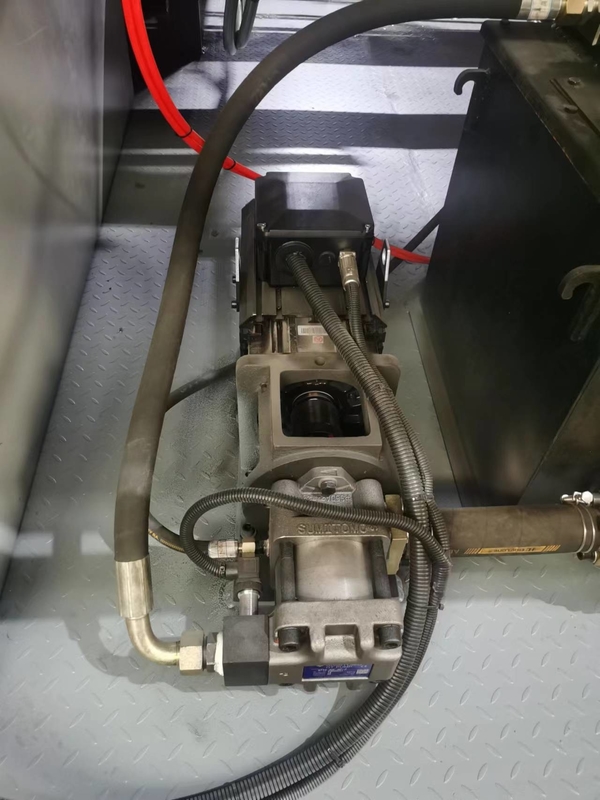

1: the mold head mechanism: the use of the split type of the head, not channeling material, more uniform, more uniform, plating processing, not accumulating material, the material is more smooth.

2:Adjusting

Open the ball valve at the oil outlet (the handle is in the same direction as the oil pipe) and the cooling water switch.

Insert the key into the key switch of the key power switch, turn to the right, and the power indicator light is on, indicating that the machine is powered on. (Also note: A 220VAC automatic air switch and a 24VDC automatic air switch must be connected in the electrical box.)

After the temperature control system reaches the temperature or after confirming the empty screw and the empty die, jog the main extrusion start button, then turn on the speed switch, and rotate the speed potentiometer to see if the motor steering meets the arrow on the belt cover. Direction, if not, replace any two phases in the three-phase line of the main motor junction box.

| SPECIFICATION | SLBK-55 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3400x2200x2200 |

| TOTAL WEIGHT | TON | 5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-400 |

| PLATEN SIZE(WxH) | MM | 260X330 |

| MAX MOULD SIZE(WxH) | MM | 300x330 |

| MOLD THICKNESS | MM | 125-220 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 11 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 32 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 13 |

![]()