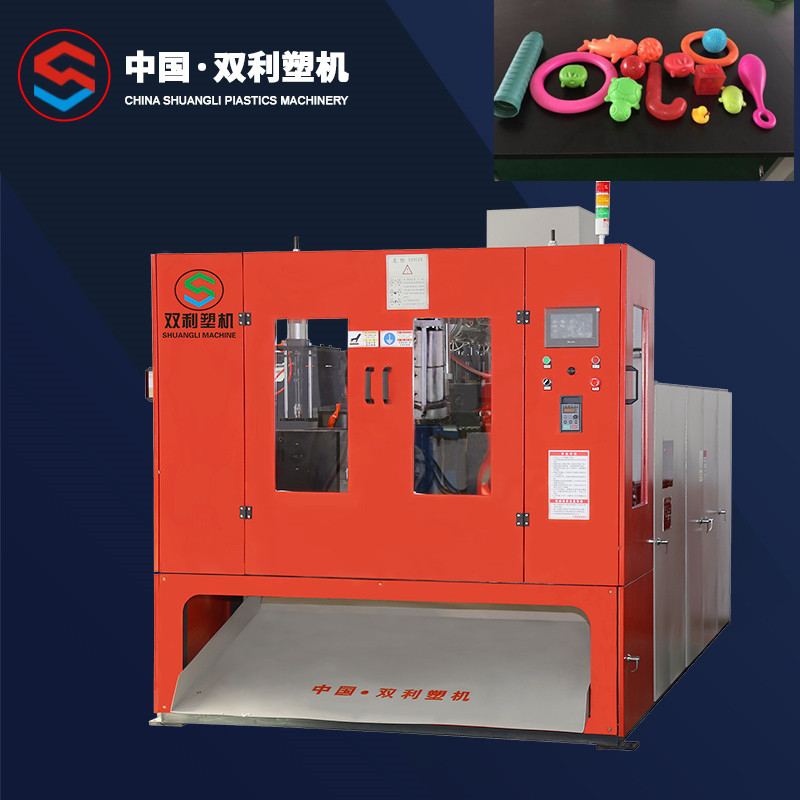

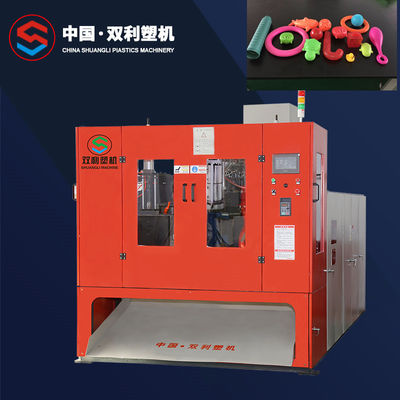

1 Layer 2l PP Blow Moulding Machine 1 Head Automatic PET Molding

-

High Light

1 layer PP Blow Moulding Machine

,2l PP Blow Moulding Machine

,1 head automatic PET blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity2L

-

StationDouble

-

ProductPlastic Kid Toys

-

LayerOne

-

Die HeadOne

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLX-55

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

1 Layer 2l PP Blow Moulding Machine 1 Head Automatic PET Molding

One Head One Layer Double Station Blow Molding Machine for Plastic Kid Toys SLX-55

SLX series:

1: shuttle blow molding machine is suitable for producing plastic products of PE/PP/EVA/ABS/K material/ TPU, nylon and other materials below 5l All parts of the machine is made by advanced numerical control equipment with high precision. And equipped with imported hydraulic, pneumatic and electrical parts of famous brand, it has stable equipment performance and simple handling.

2 This machine is suitable for bottles, detergent bottles, oil pot, plastic toys, cosmetics bottles, beverage bottles, chemical Hardware

etc..

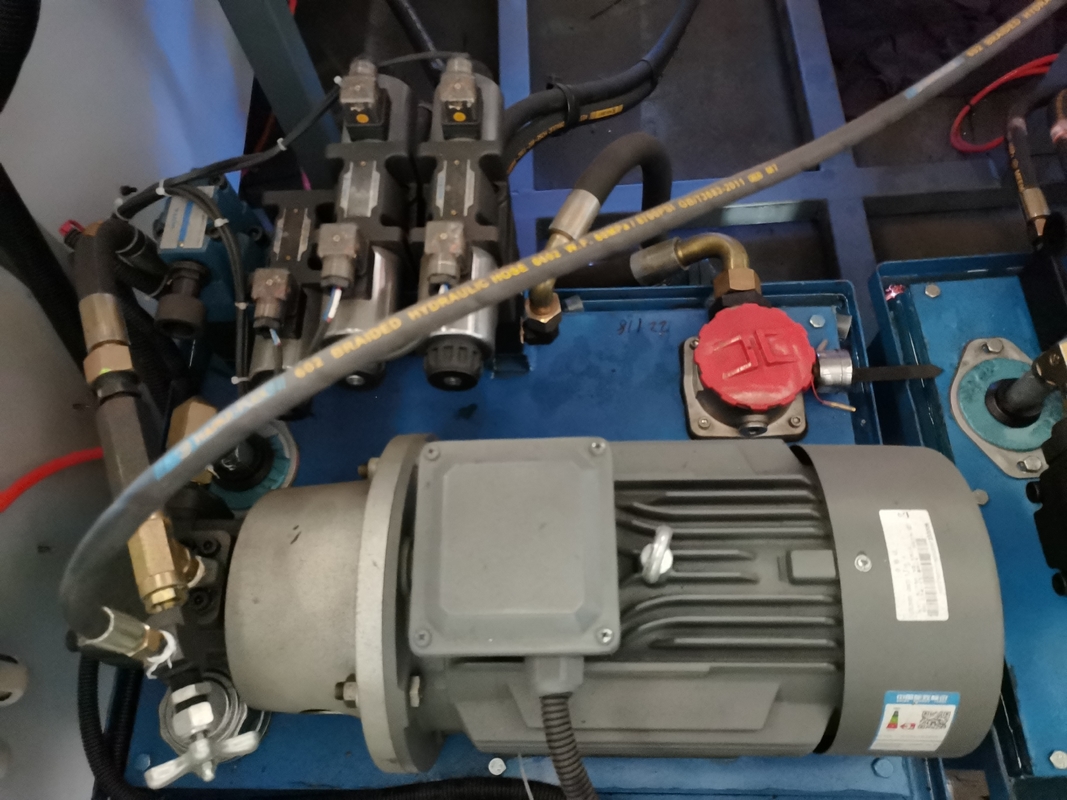

3. Notes before using the blow molding machine

Please use proper hydraulic oil (viscosity 46 ± 4.6Csi). Before using the machine, fill the oil until the oil level is above the specified scale.

The voltage of the power supply should be within the range of ±10% of the voltage stated on the nameplate of the machine.

The frequency should be within the range of ±10% of the frequency stated on the nameplate of the blow molding machine.

| SPECIFICATION | SLX-55 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3200x1600x2200 |

| TOTAL WEIGHT | TON | 3T |

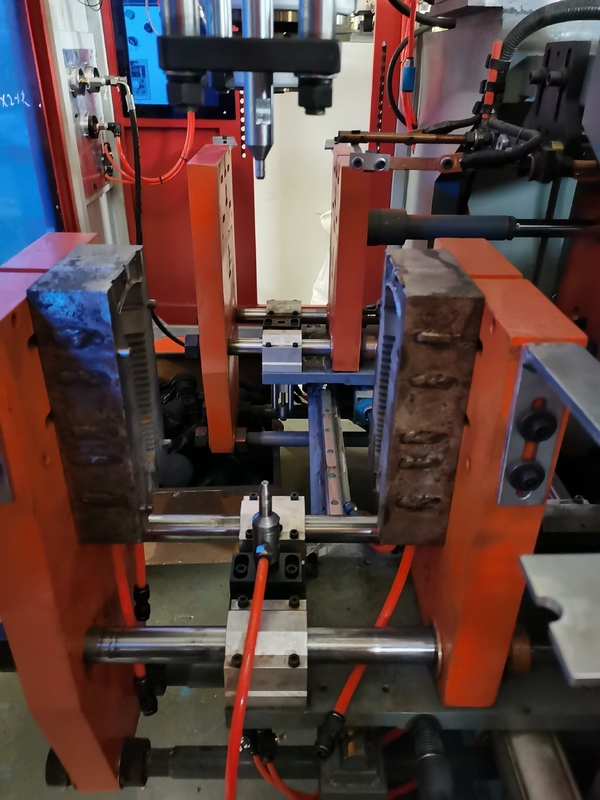

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-420 |

| PLATEN SIZE(WxH) | MM | 360X300 |

| MAX MOULD SIZE(WxH) | MM | 240x400 |

| MOLD THICKNESS | MM | 105-200 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 7.5(11) |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 1320 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 22 |

| FAN POWER OF SCREW | KW | 0.42 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 8 |

![]()