Lubricant Bottle PP Blow Moulding Machine 3 Head EVA Double Station

-

High Light

lubricant bottle PP Blow Moulding Machine

,3 head PP Blow Moulding Machine

,EVA double station blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity2L

-

StationDouble

-

ProductPlastic Lubricant Oil Bottle

-

LayerOne

-

Die HeadOne

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLX-55

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Lubricant Bottle PP Blow Moulding Machine 3 Head EVA Double Station

One Head One Layer Double Station Blow Molding Machine for Plastic Lubricant Oil Bottle SLX-65

SLX series:

1: This machine is suitable for PP, PE, EVA, PS, ABS, TPR, TPV and other raw materials such as blow molding.

2: SLX series are Shuangli company pioneered the gas -liquid combination of new type blow moulding machine, superior performance,

stable operation, simple operation, affordable and Characteristic

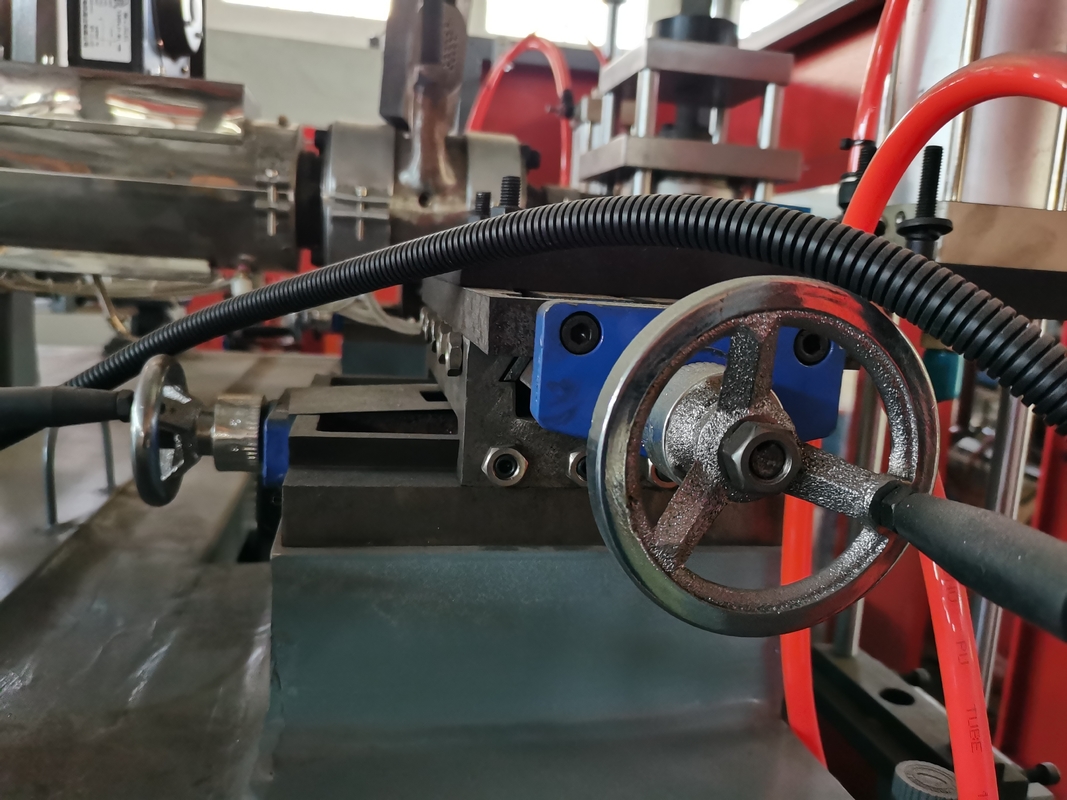

3: The screw and the barrel used in the machine are made from nitride steel. They are characterized by high strength, good wear resistance, and high erosion resistance.

The platens and tiebars in the clamping unit are made from high quality material. The clamping force is strong and the mold size is large.

The specially designed balance-type clamping unit and the attached hydraulic system make the machine run more smoothly.

The blow molding machine features rapid injection, smooth low pressure rapid clamping. It uses single layer offset spider for the die-head and central-feeding-style divider bracket to improve production efficiency and quality of the products, low backpressure, no blind angle and faster color change.

The hydraulic unit is specially designed with less loading and heating, more energy saved. Also, the hydraulic oil temperature is strictly controlled by PLC (programmable logic controller), ranging from 40°C~50°C. To extend the service time of oil and related parts, oil absorbing and returning filters are designed to keep oil clean and protect the hydraulic unit.

| SLX-55 | ||

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 2 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3200x1600x2200 |

| TOTAL WEIGHT | TON | 3T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 40 |

| PLATEN OPENING STROKE | MM | 120-420 |

| PLATEN SIZE(WxH) | MM | 360X300 |

| MAX MOULD SIZE(WxH) | MM | 240x400 |

| MOLD THICKNESS | MM | 105-200 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 55 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 45 |

| BARREL HEATING POWER | KW | 12 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 7.5(11) |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 1320 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 150 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 22 |

| FAN POWER OF SCREW | KW | 0.42 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 8 |

![]()