-

High Light

950 bph bottle moulding machines shuangli

,950 bph bottle moulding machine shuangli

,SLX-65 950 bph bottle moulding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

StationDouble

-

ProductPlastic Cosmetics Bottle

-

LayerOne

-

Die HeadOne

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLX-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

5L Cosmetics Bottle Extrusion Blow Molding Machine

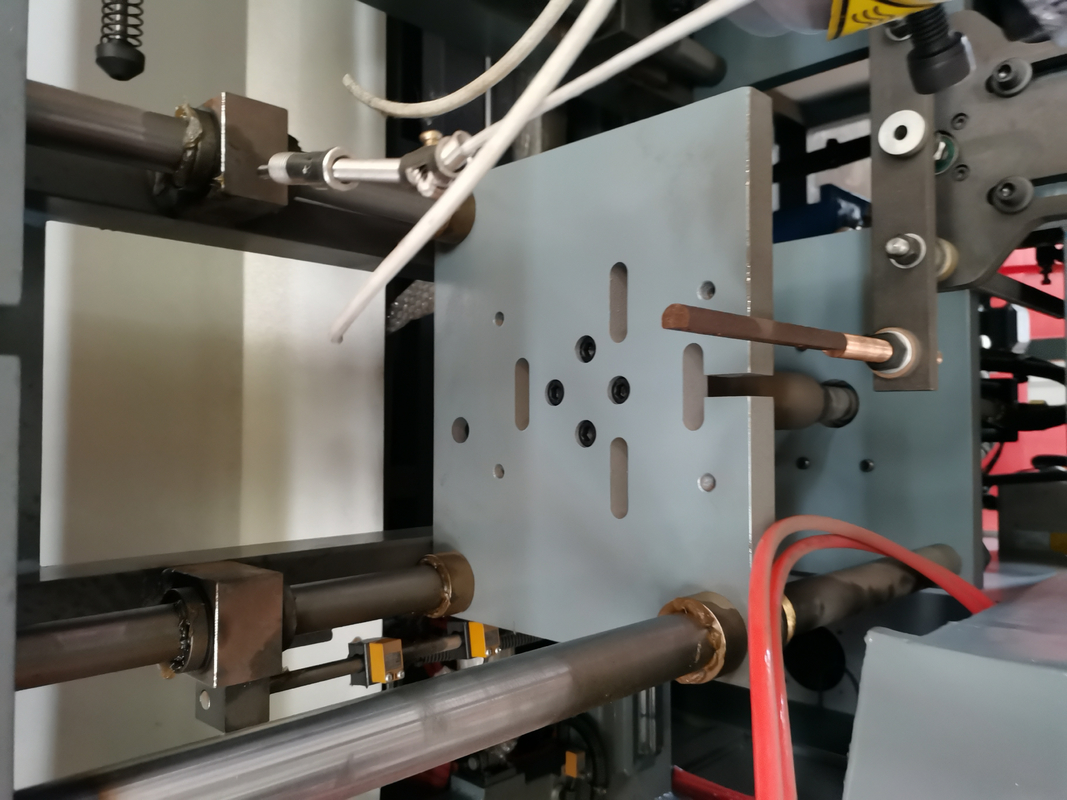

One Head One Layer Double Station Blow Molding Machine for Plastic Cosmetics Bottle SLX-65

SLX series:

1: This machine is suitable for PP, PE, EVA, PS, ABS, TPR, TPV and other raw materials such as blow molding.

2: SLX series are Shuangli company pioneered the gas -liquid combination of new type blow moulding machine, superior performance,

stable operation, simple operation, affordable andCharacteristic

3: The production efficiency can be improved by repeating the cycle continually.

Automatic circulation of timer.

Use computer to control circuits. High resolution LCD (liquid crystal display) screen is equipped. According to the modification to the process, the

action program can be modified at any time to ensure a convenient operation, reliable performance and quick maintenance.

Auxiliary equipment specially designed for automatic production is ready for you to choose, for example: humidity removing set, dryer, vacuum

suction machine, mold temperature controller, cooler, granulator, mixer, etc.

Safety gates have the dual functions of safe and convenient adjustment. The pneumatic components are installed on the safety gates and the

former safety gates are installed with protection device of travel switch.

| SLX-65 | ||

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6 |

| OUPUT(DRY CYCLE) | PC/HR | 950x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 3800x1800x2600 |

| TOTAL WEIGHT | TON | 3.8T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 170-520 |

| PLATEN SIZE(WxH) | MM | 450x400 |

| MAX MOULD SIZE(WxH) | MM | 330x500 |

| MOLD THICKNESS | MM | 175-250 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 11(15) |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 80 |

| CENTER DISTANCE OF FOUR DIE | MM | 60 |

| CENTER DISTANCE OF SIX DIE | MM | 60 |

| MAX DIE-PIN DIAMETER | MM | 260 |

| POWER | ||

| MAX DRIVE POWER | KW | 26 |

| TOTAL POWER | KW | 32 |

| FAN POWER OF SCREW | KW | 0.42 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.5 |

| AVERAGE ENERGY CONSUMPTION | KW | 13 |

![]()