4 Head High Speed Blow Molding Machine Single Station 5l Blowing Machine For Plastic Bottle

-

High Light

4 head High Speed Blow Molding Machine

,single station High Speed Blow Molding Machine

,5l blowing machine for plastic bottle

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

Plastic Cosmetic Bottle1000 Pcs/hour

-

View Stripe LineYes

-

Die Head4 Heads

-

StationDouble Or Single

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

4 Head High Speed Blow Molding Machine Single Station 5l Blowing Machine For Plastic Bottle

(Double Station High Speed 4 Die Heads Blow Molding Machine for Plastic Cosmetic Bottle with View Stripe Line

SLBU series:

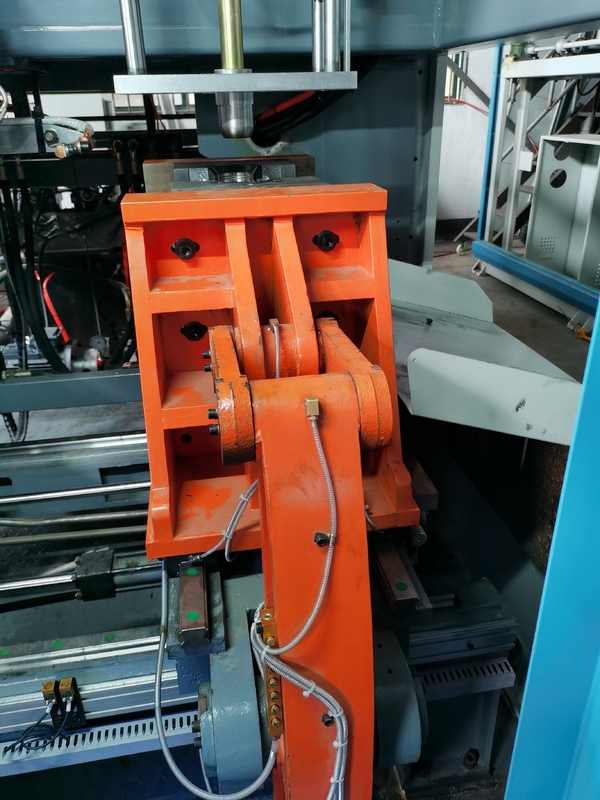

1: this machine is suitable for the production of 200ML- 5L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speed faster, run more smoothly for 4 die head for plastic cosmetic bottle with view stripe line.

2; With 4 head system: all the use of 38CRMOALA and other materials, the precision machining and heat treatment. 4 die heads is optional.

hydraulic system: full hydraulic double proportional hydraulic control, equipped with imported famous brand hydraulic valve and oil pump, stable, reliable.

3.Before each shift, you must add lubricant to each moving part. (manipulator, manipulator guide, open and close die guide)

The swing arm can be added once every (3 – 4) days. Heating machine large chain small chain can be used once a month. Always check if the main unit reducer and the warmer reducer are short of oil. The main bearing can be added once every 3 months.

(Check whether the moving parts are firm before the production, whether the screws are loose or not, especially in the place where the impact force is strong, and whether the belt transmission part is abnormal.

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()