6 Head High Speed Blow Molding Machine Double Station PVC Medicine Bottle

-

High Light

6 head High Speed Blow Molding Machine

,double station High Speed Blow Molding Machine

,PVC medicine bottle blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

ProductPlastic Medicine Bottle

-

Machine TypeFull Automatic

-

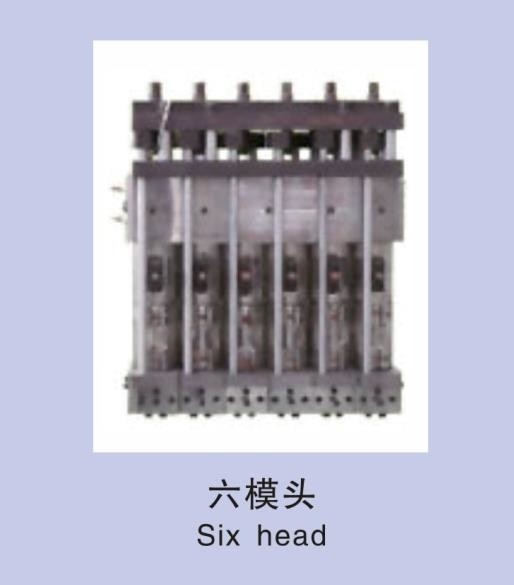

Die Head6 Heads

-

StationDouble Or Single

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

6 Head High Speed Blow Molding Machine Double Station PVC Medicine Bottle

U series Double Station High Speed 1 Layer 6 Die Heads Blow Molding Machine for Plastic Medicine Bottle

SLBU series:

1. It is suitable for producing PE, HDPE, PP, PVC, PETG, PS so on, plastic containers and bottles in all shapes are available, the max. Product volume is up to 5L.

2. Double or Single station single die head design, very easy to operate and maintenance.

3. Most components of the blow moulding machine are from famous world brand.

4. Fully automatic process with low power consumption, high efficiency, quick and safe operation, easy for maintenance.

5. Multiple screw available for double layer .

6. Auto deflashing device available, can remove the extra parts of bottles.

7. Auto lubricant system controlled by PLC.

Warranty: One year from the date from the date of Installation or acceptance of the Plant whichever comes first.

Free Spare Parts : Digital instrument, Sealing, Stretching cylinder seal ring, Mould-adjustment wrench, Furnace temperature table, Furnace heating tube and other relative vulnerable part .

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()