Double Station 1 Layer Barrel Blow Molding Machine High Speed For Plastic Bottle

-

High Light

double station barrel blow molding machine

,1 layer barrel blow molding machine

,high speed blow moulding machine for plastic bottle

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity5L

-

RobotOptional

-

Machine TypeAutomatic Type

-

ProductPlastic Civil Barrel.

-

StationDouble Station

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBU-65

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Double Station 1 Layer Barrel Blow Molding Machine High Speed For Plastic Bottle

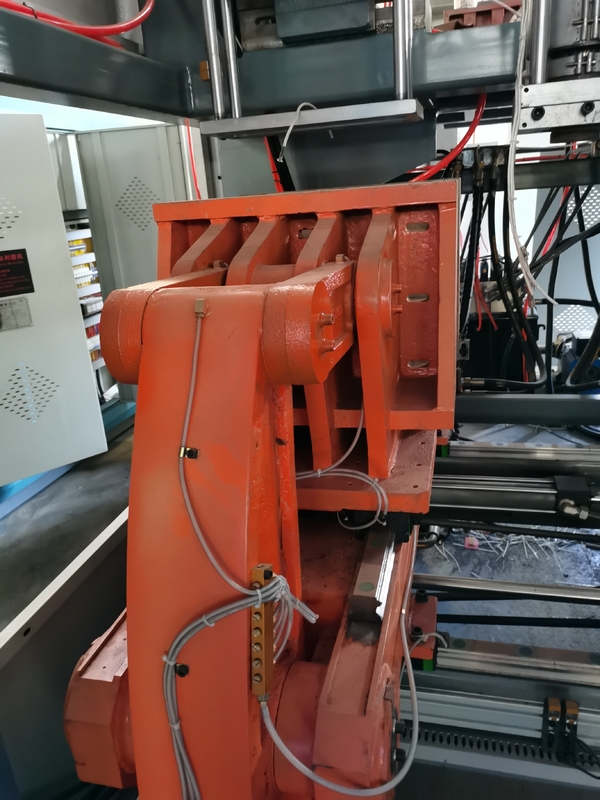

U series Double Station High Speed 1 Layer 1 Die Head Blow Molding Machine for Plastic Civil Barrel.

SLBU series:

.

1: this machine is suitable for the production of 5L plastic hollow products, the use of curved elbow lock system, low energy consumption, the center of the lock, the lock force, speed faster, run more smoothly

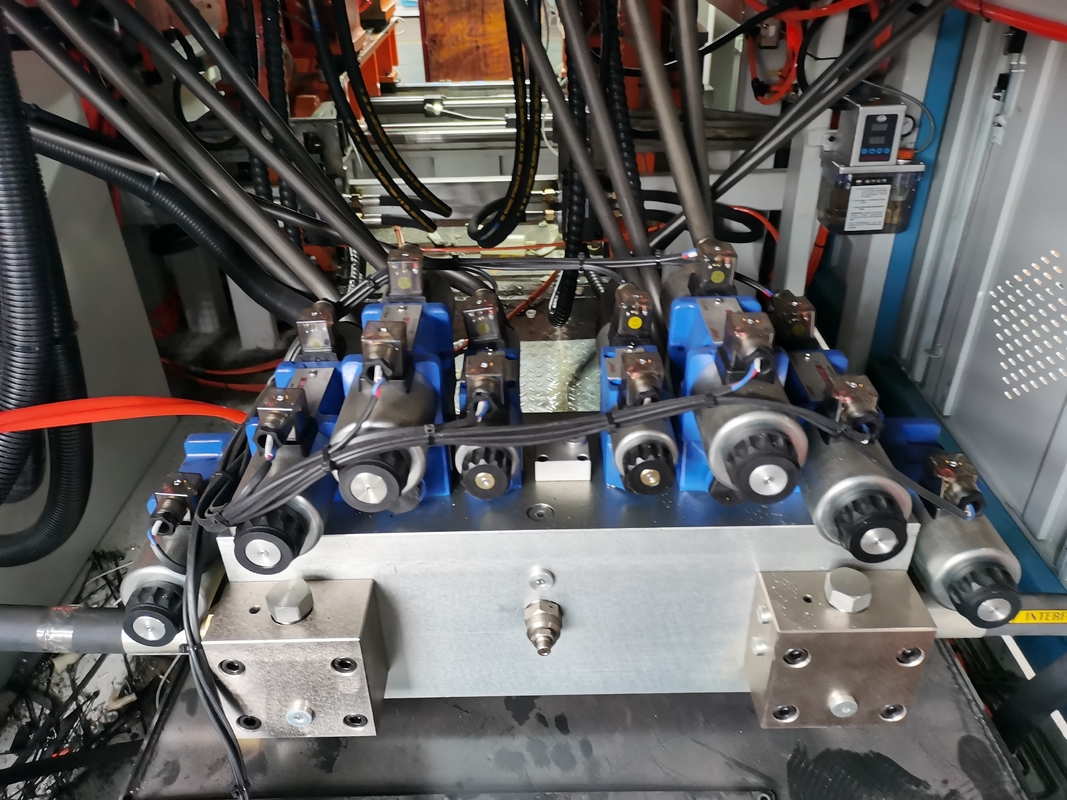

2: With 2 die opening and closing system: specially designed for Heng lock mould mechanism using a high pressure mode locking, locking plate stress in the centre of the template, clamping force, openThe rigid lock template, even if the ultra wide die is also fitted.

3; The equipment is suitable for PE, PVC, PP, PC, PS, ABS, EVA, PA, PET, EVOH, PVDC, PAN, PPE, TPE, POM, etc. (whether imported or domestic raw materials).

Please refer to the electrical schematic diagram for the internal wiring of the electrical box (see Appendix);

Please note! Non-professionals please do not open the electrical box door for maintenance work;

| SPECIFICATION | SLBU-65 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 5 |

| NUMBER OF DIE HEAD | SET | 1,2,3,4,6,8 |

| OUPUT(DRY CYCLE) | PC/HR | 1000x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 4000x2300x2200 |

| TOTAL WEIGHT | TON | 6.5T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 65 |

| PLATEN OPENING STROKE | MM | 220-520 |

| PLATEN SIZE(WxH) | MM | 400x430 |

| MAX MOULD SIZE(WxH) | MM | 460x430 |

| MOLD THICKNESS | MM | 255-280 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 65 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 70 |

| BARREL HEATING POWER | KW | 15 |

| NUMBER OF HEATING ZONE | ZONE | 3 |

| EXTRUDER MOTOR RATED POWER | KW | 15 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 2-5 |

| POWER OF DIE HEATING | KW | 6 |

| CENTER DISTANCE OF DOUBLE DIE | MM | 130 |

| CENTER DISTANCE OF THREE DIE | MM | 110 |

| CENTER DISTANCE OF FOUR DIE | MM | 100 |

| CENTER DISTANCE OF SIX DIE | MM | 80 |

| MAX DIE-PIN DIAMETER | MM | 180 |

| POWER | ||

| MAX DRIVE POWER | KW | 18 |

| TOTAL POWER | KW | 50 |

| FAN POWER OF SCREW | KW | 2.4 |

| AIR PRESSURE | MPA | 0.6 |

| AIR CONSUMPTION | M3/MIN | 0.4 |

| AVERAGE ENERGY CONSUMPTION | KW | 18 |

![]()