50l Accumulator Blow Moulding Machine Double Station 1 Head

-

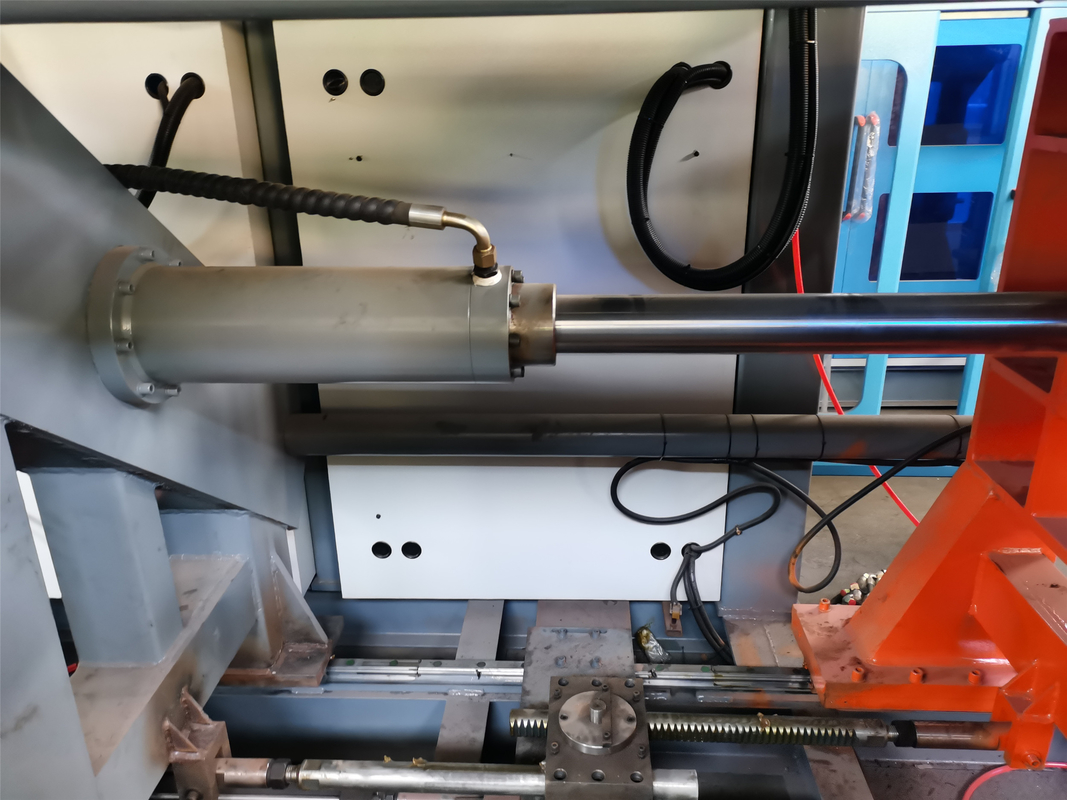

High Light

double station Accumulator Blow Moulding Machine

,50l Accumulator Blow Moulding Machine

,1 head double station blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity50L

-

StationDouble

-

Clamping TypeC Type-Tie Bar

-

ProductPlastic Tool Box

-

Die Head1 Head

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBS-100

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

50l Accumulator Blow Moulding Machine Double Station 1 Head

Double Station 1 Die Head Accmulator Type Plastic Blow Molding Machine For Plastic Tool Box

SLBS series: (German model)

1: linear guide support single frame, finite element analysis of the design, to ensure adequate clamping force.

2.The cooling system consists of an oil cooler, barrel cooling, blow head cooling, gearbox cooling, and mold cooling. The oil cooler in the cooling system is the protector of the hydraulic system. Excessive oil temperature in the hydraulic system can make the machine work abnormally. The temperature rise of the hydraulic oil is mainly caused by the heating of the system itself, and the power consumption is represented by the loss of flow and pressure, and finally converted into heat energy. The oil temperature of the hydraulic system is required to be 30-55 degrees. The heat dissipation area of the fuel tank and the pipeline can not meet this requirement. Therefore, the oil cooler is installed to cool the hydraulic oil to ensure the normal working temperature of the hydraulic oil. The barrel of the extrusion device has a cooling device. The barrel cooling ensures that the plastic is smoothly transported forward in the solid state. At the same time, it is used to remove the heat transfer from the barrel to the hopper and the gear box, preventing the material from rising and sticking and causing uneven feeding.

| SPECIFICATION | SLBS-100 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 50 |

| OUPUT(DRY CYCLE) | PC/HR | 300x2 |

| MACHINE DIMENSION (LxWxH ) | MM | 6400x6400x4000 |

| TOTAL WEIGHT | TON | 20T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 200 |

| PLATEN OPENING STROKE | MM | 350-850 |

| PLATEN SIZE(WxH) | MM | 850x800 |

| MAX MOULD SIZE(WxH) | MM | 590x700 |

| MOLD THICKNESS | MM | 360-500 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 100 |

| SCREW L/D RATIO | L/D | 28 |

| MELTING CAPACITY | KG/HR | 160 |

| BARREL HEATING POWER | KW | 28 |

| NUMBER OF HEATING ZONE | ZONE | 5 |

| EXTRUDER MOTOR RATED POWER | KW | 45 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 18 |

| MAX DIE-PIN DIAMETER | MM | 260 |

| POWER | ||

| MAX DRIVE POWER | KW | 42 |

| TOTAL POWER | KW | 120 |

| FAN POWER OF SCREW | KW | 4 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 45 |

| ACCUMULATOR CAPACITY | L | 10 |

![]()