Single Station One Head Blow Molding Machine for Plastic Petroleum Drum with Parison System

SLBC series: (German model)

1: linear guide support single frame, finite element analysis of the design, to ensure adequate clamping force, not up mode. All parts of the

machine is made by advanced numerical control equipment with high precision. with user friendly PLC

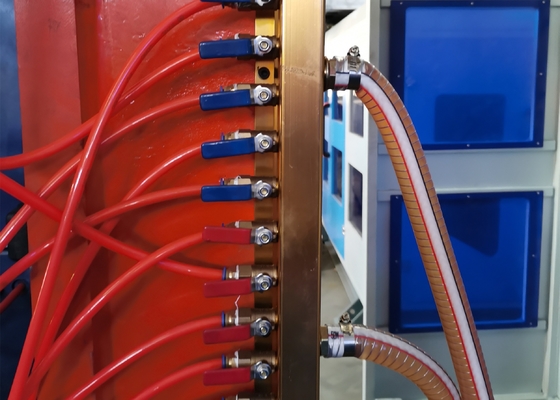

2:Connection of cooling water pipes

1) There are main places using cooling water. Please check if there is cooling water flowing in these places.

The hopper base

Avoid excessive high temperature in the hopper base causing “protrusion to the door”. The cooling water can help feeding more smooth.Blow pin

Accelerate the cooling and shape of products’ mouth and improve the production efficiency.

The mold

Control the temperature of the mold to fasten the molding of the products and ensure the quality of the products.

Hydraulic oil

| SPECIFICATION | SLBC-90 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 60 |

| OUPUT(DRY CYCLE) | PC/HR | 450 |

| MACHINE DIMENSION (LxWxH ) | MM | 6300x3400x4200 |

| TOTAL WEIGHT | TON | 14T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 260 |

| PLATEN OPENING STROKE | MM | 400-1200 |

| PLATEN SIZE(WxH) | MM | 900x1000 |

| MAX MOULD SIZE(WxH) | MM | 750x1200 |

| MOLD THICKNESS | MM | 410-700 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 90 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 140 |

| BARREL HEATING POWER | KW | 20 |

| NUMBER OF HEATING ZONE | ZONE | 5 |

| EXTRUDER MOTOR RATED POWER | KW | 45 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 4 |

| POWER OF DIE HEATING | KW | 18 |

| MAX DIE-PIN DIAMETER | MM | 400 |

| POWER | ||

| MAX DRIVE POWER | KW | 57 |

| TOTAL POWER | KW | 105 |

| FAN POWER OF SCREW | KW | 4 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 38 |

| ACCUMULATOR CAPACITY | L | 8 |

![]()