Plastic Accumulator Blow Moulding Machine Tool Box 1 Layer Automatic HDPE Bottle Blowing Machine

-

High Light

plastic Accumulator Blow Moulding Machine

,tool box Accumulator Blow Moulding Machine

,1 layer automatic PET bottle blowing machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity160L

-

StationSingle

-

ProductPlastic Tool Box With Parison System

-

Layer1 Layer

-

Parison SystemOptional

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-120

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Plastic Accumulator Blow Moulding Machine Tool Box 1 Layer Automatic HDPE Bottle Blowing Machine

Single Station High One Head Blow Molding Machine for Plastic Tool Box with Parison System

SLBC series: (German model)

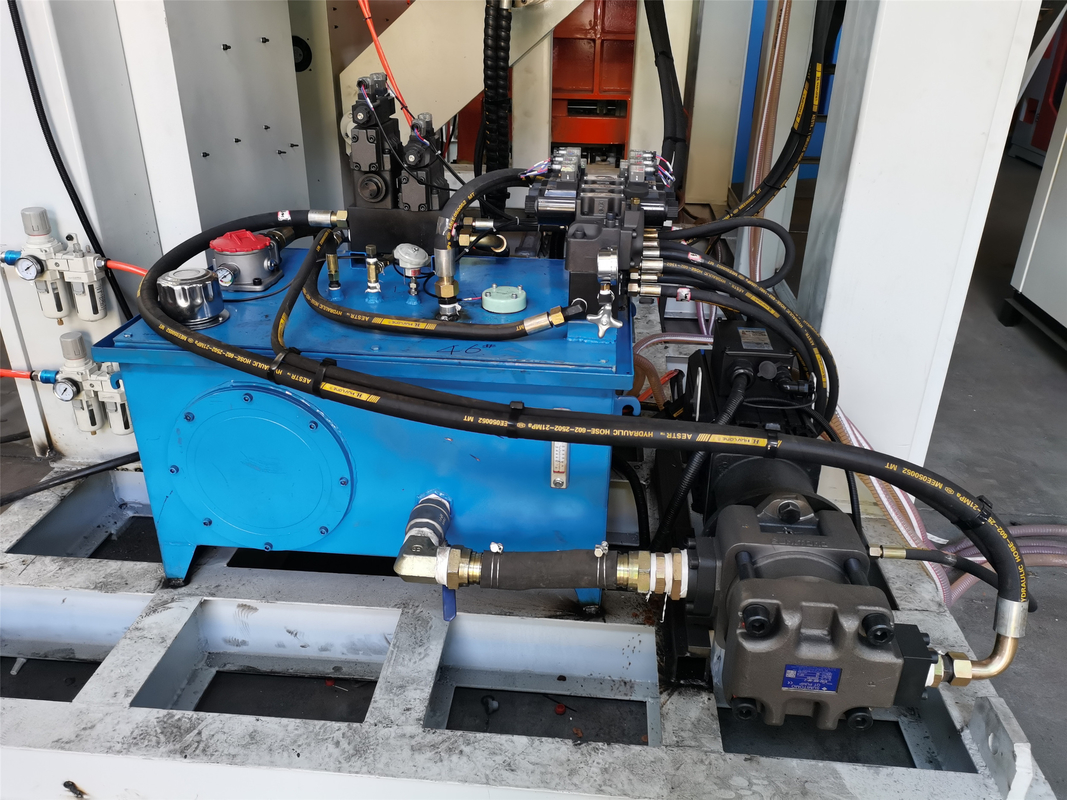

1: large opening stroke, central locking, locking force equilibrium, no deformation. All parts of the machine is made by advanced numerical control

equipment with high precision. with PLC SIEMENS.

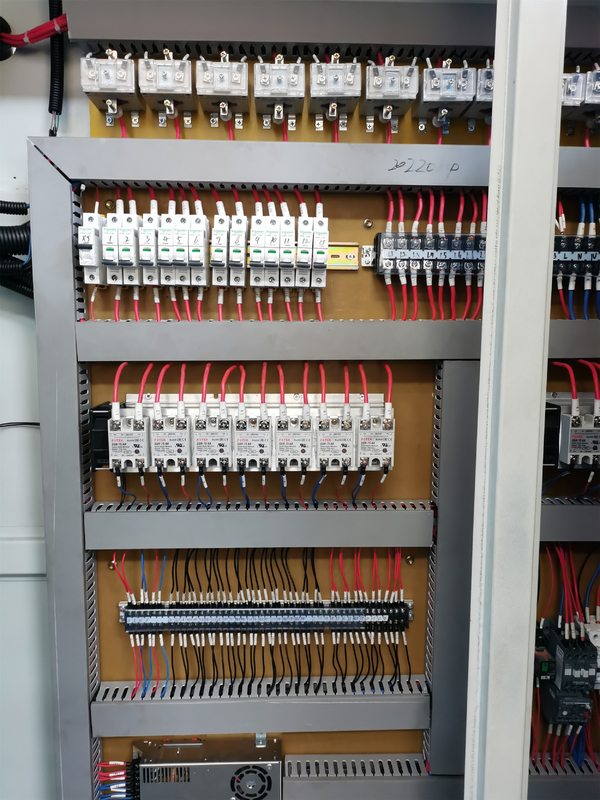

2: Due to different countries and regions with different power supply systems, before connecting the power supply, please be sure to strictly check

if the power supply system of total power, line voltage, phase voltage and frequency are suitable to the blow molding machine.

After the blow molding machine is installed and fixed, please check if the components and wires of the electric unit in the power distribution box of

the machine are loosened or damaged in transportation. If there are, please repair them and then check them again. When making sure that

everything is ok, the power supply can be connected. Install a proper fuse-free switch as the power switch.

| SPECIFICATION | SLBC-120 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 300 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x4200x6200 |

| TOTAL WEIGHT | TON | 22T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 800 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 120 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 280 |

| BARREL HEATING POWER | KW | 42 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 90 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 38 |

| MAX DIE-PIN DIAMETER | MM | 500 |

| POWER | ||

| MAX DRIVE POWER | KW | 125 |

| TOTAL POWER | KW | 180 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 72 |

| ACCUMULATOR CAPACITY | L | 30 |

![]()