Traffic Product PP Accumulator Extrusion Blow Molding Machine 30-200L Bottle

-

High Light

traffic product accumulator extrusion blow molding machine

,PP accumulator extrusion blow molding machine

,160l PET bottle blower machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity160L

-

StationSingle

-

RobotOptional

-

ProductPlastic Traffic Product

-

Die Head1 Head

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-120

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Traffic Product PP Accumulator Extrusion Blow Molding Machine 30-200L Bottle

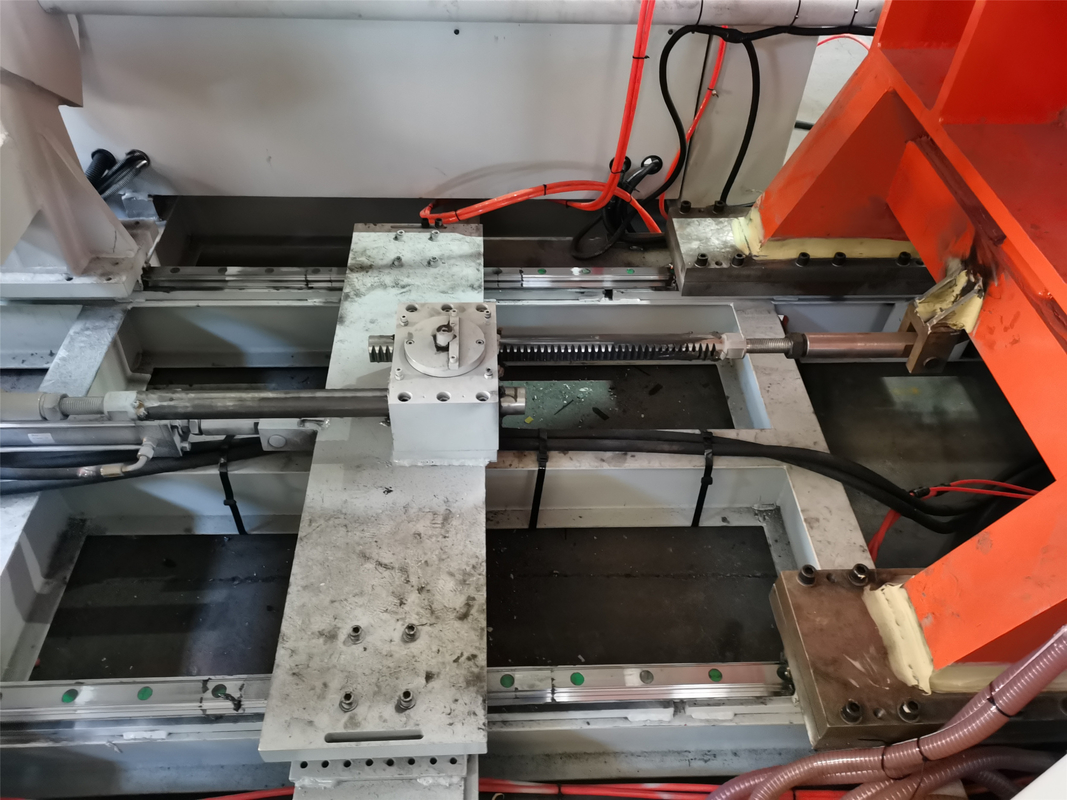

Single Station One Head Blow Molding Machine for Plastic Traffic Product with Parison System

SLBC series: (German model)

1: linear guide support single frame, finite element analysis of the design, to ensure adequate clamping force, not up mode.

And equipped with imported hydraulic, pneumatic and electrical parts of famous brand, it has stable equipment performance and simple handling.

2: large opening stroke, central locking, locking force equilibrium, no deformation. All parts of the machine is made by advanced numerical control

equipment with high precision.

3: Lubricant

Please select proper lubricant using regularly and quantitatively, so as to ensure the working efficiency of the blow molding machine machine and

also to extend its service life.

Note:

(a) Please don’t mix hydraulic oil and lubricant of different product names.

(

b) The driving motor of the pumps can not be started within three hours after its oil tank is filled in order to discharge the air in the oil fluid.

| SPECIFICATION | SLBC-120 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 300 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x4200x6200 |

| TOTAL WEIGHT | TON | 22T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 800 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 120 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 280 |

| BARREL HEATING POWER | KW | 42 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 90 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 38 |

| MAX DIE-PIN DIAMETER | MM | 500 |

| POWER | ||

| MAX DRIVE POWER | KW | 125 |

| TOTAL POWER | KW | 180 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 72 |

| ACCUMULATOR CAPACITY | L | 30 |

![]()