160l Accumulator Blow Moulding Machine Single Station ABS Water Tank

-

High Light

single station Accumulator Blow Moulding Machine

,160l Accumulator Blow Moulding Machine

,ABS water tank blow molding machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity160L

-

StationSingle

-

Die Head1 Head

-

ProductPlastic Water Tank

-

ParisonB&R

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-120

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

160l Accumulator Blow Moulding Machine Single Station ABS Water Tank

Single Station One Head Blow Molding Machine for Plastic Water Tank with Parison System

SLBC series: (German model)

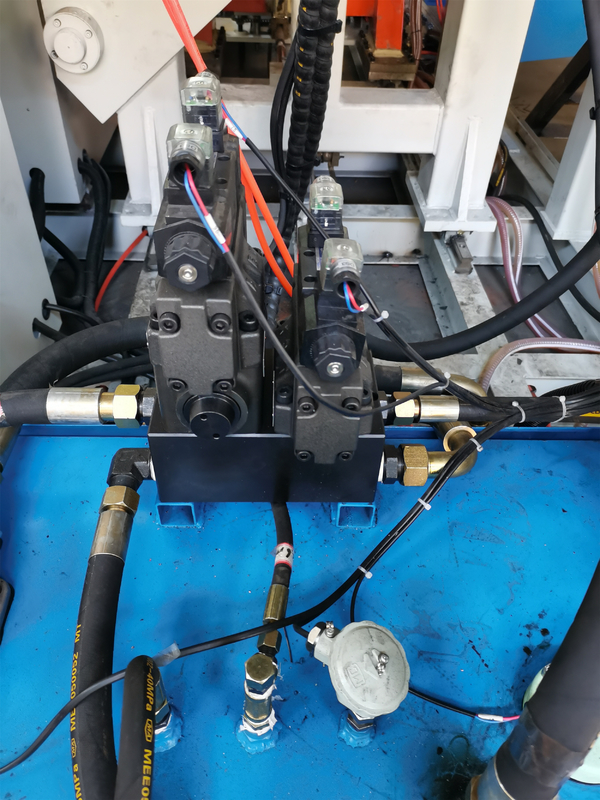

1: (1) Steps of filling hydraulic oil

Uncover the cap of the oil tank and fill proper hydraulic oil until the oil level reaches the top point of the oil-level gauge. The oil level in the oil tank

will decline due to every cylinder and pipeline will be full of oil after the first running of the machine, hydraulic oil should be added at this time to

keep the oil level above the oil scale.

Note:

(a) Please don’t mix hydraulic oil and lubricant of different product names.

(b) Starting the oil pump is not allowed within three hours after filling hydraulic oil into oil tank, to make sure the gas in the hydraulic oil can be removed.

2: the whole system is equipped with safety protection grating, to ensure the safety of the production process without acciden.with PLC SIEMENS.

| SPECIFICATION | SLBC-120 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 300 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x4200x6200 |

| TOTAL WEIGHT | TON | 22T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 800 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 120 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 280 |

| BARREL HEATING POWER | KW | 42 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 90 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 38 |

| MAX DIE-PIN DIAMETER | MM | 500 |

| POWER | ||

| MAX DRIVE POWER | KW | 125 |

| TOTAL POWER | KW | 180 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 72 |

| ACCUMULATOR CAPACITY | L | 30 |

![]()