Pallet Robot Plastic Extrusion Blow Moulding Machine 160l Bottle Water Blowing Machine

-

High Light

pallet plastic extrusion blow moulding machine

,robot plastic extrusion blow moulding machine

,160l Bottle Water Blowing Machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity160L

-

StationSingle

-

ProductPlastic Pallet With Robot

-

RobotOptional

-

Parison SystemOptional

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-120

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Pallet Robot Plastic Extrusion Blow Moulding Machine 160l Bottle Water Blowing Machine

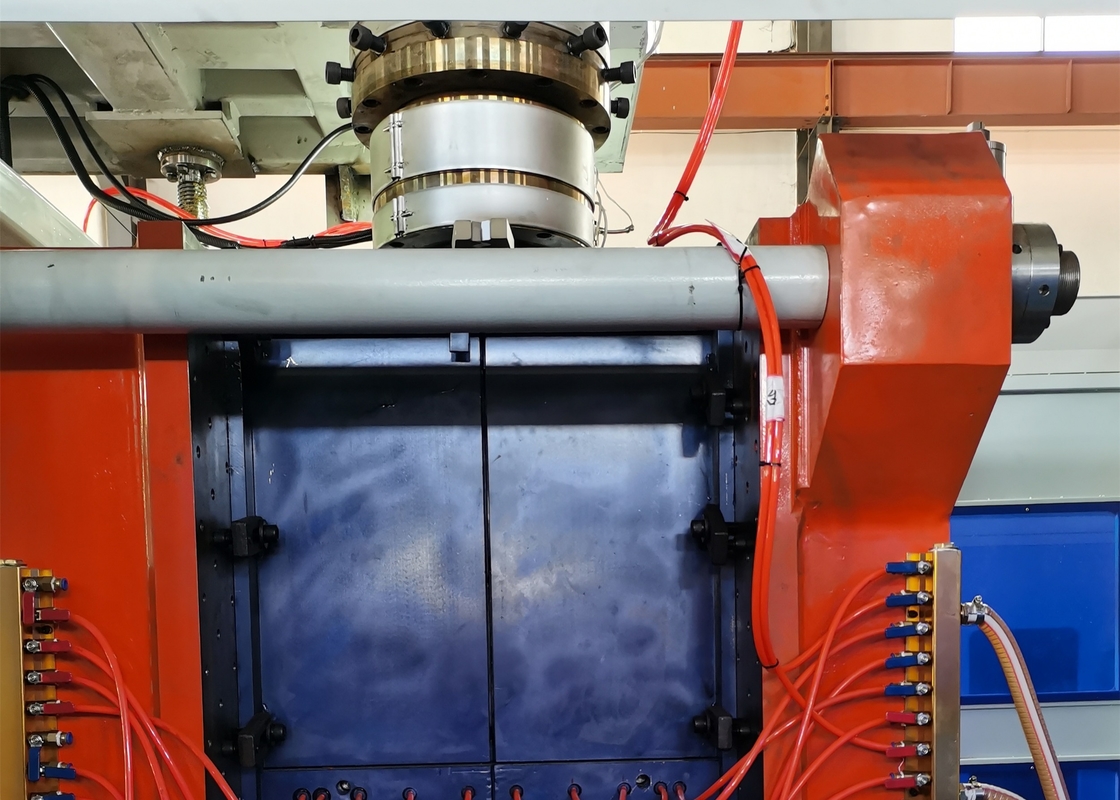

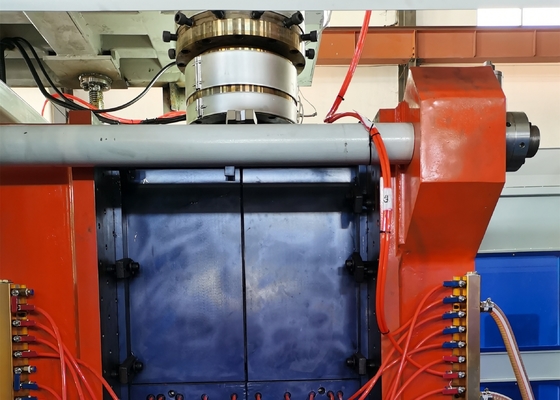

Single Station High One Head Blow Molding Machine for Plastic Pallet with Robot

SLBC series: (German model)

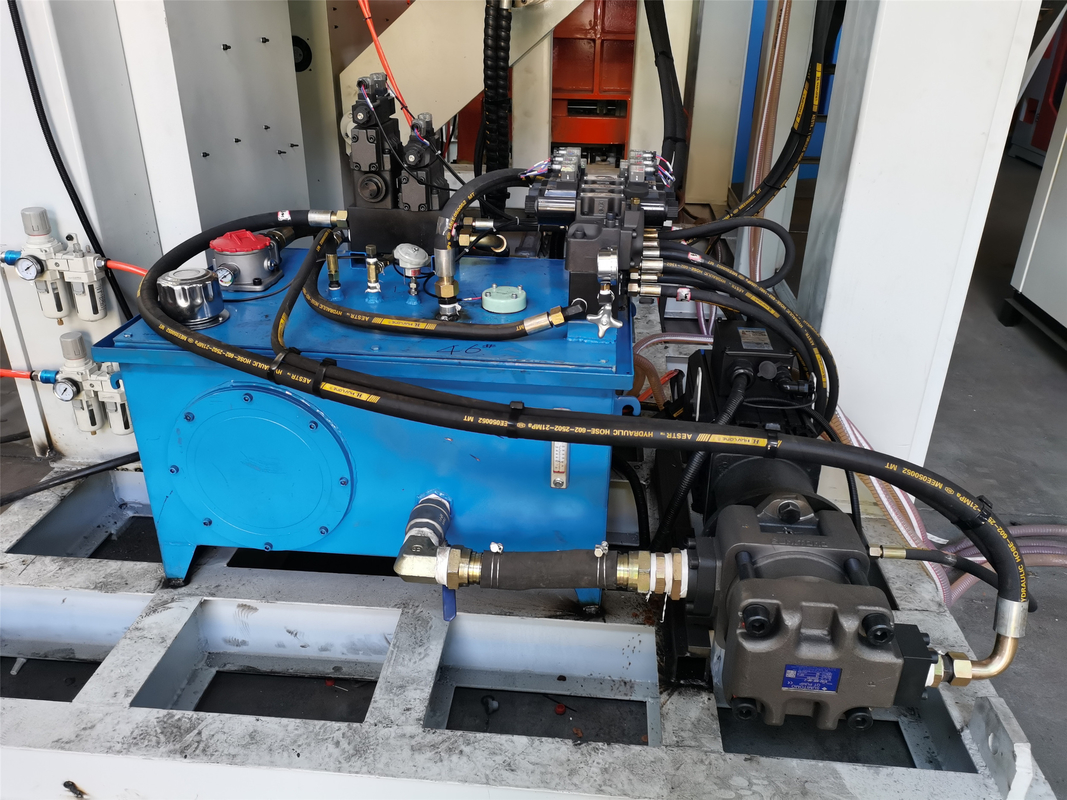

1: linear guide support single frame, finite element analysis of the design, to ensure adequate clamping force, not up mode.with PLC SIEMENS.

2,Dust and dirt on chromeplated parts (for example: tiebars, guide bars and guide bush), and all the piston rods of oil tank should be removed carefully to avoid damaging the quality of sealing components and the chromeplated surface. Smear a thin layer of lubricant on it after cleaning.

3,After the blow molding machine is cleaned, please make sure that there is no tool or rag left on the machine.

4,Please keep enough space around the machine. After filling the hydraulic oil or lubricants oil, please clean the leaking oil as soon as possible. Before operating the machine, please clean all the sundries on the surface or near the barrel in case of fire.

| SPECIFICATION | SLBC-120 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 300 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x4200x6200 |

| TOTAL WEIGHT | TON | 22T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 800 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 120 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 280 |

| BARREL HEATING POWER | KW | 42 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 90 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 38 |

| MAX DIE-PIN DIAMETER | MM | 500 |

| POWER | ||

| MAX DRIVE POWER | KW | 125 |

| TOTAL POWER | KW | 180 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 72 |

| ACCUMULATOR CAPACITY | L | 30 |

![]()