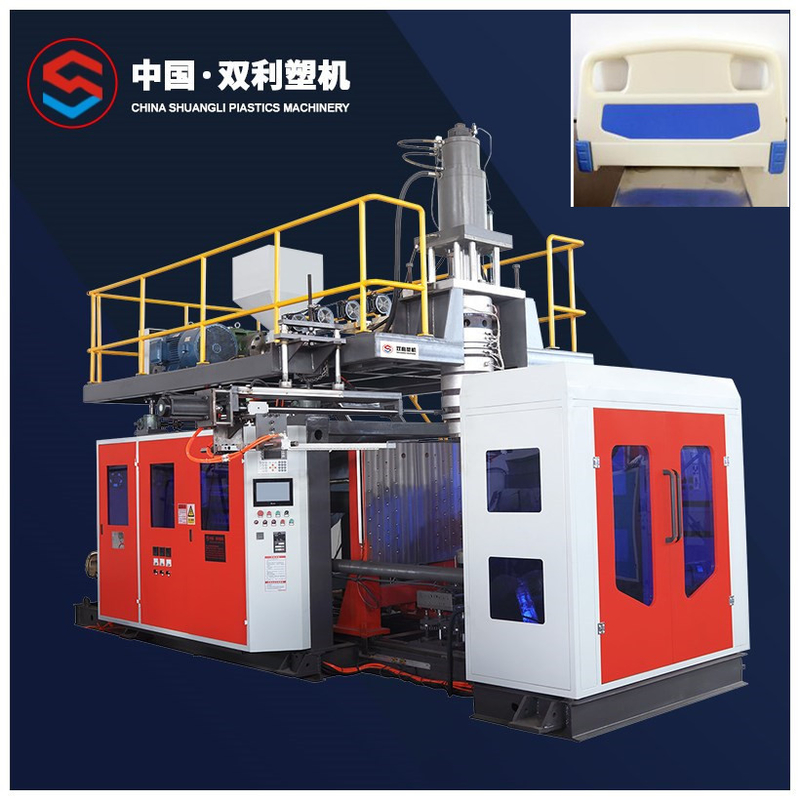

30l Medical Bed Accumulator Blow Molding Machine Single Station Water Bottle

-

High Light

30l accumulator blow molding machine

,medical bed accumulator blow molding machine

,single station water bottle blow moulding machine

-

MaterialPE,PP,EVA,ABS

-

Max Capacity30L

-

ProductPlastic Medical Bed

-

Clamping TypeC Type-Tie Bar

-

Die HeadAccmulator Type

-

StationSingle Station

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-80

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

30l Medical Bed Accumulator Blow Molding Machine Single Station Water Bottle

Single Station 1 Die Head Accmulator Type Plastic Blow Molding Machine For Plastic Medical Bed

SLBC series: (German model)

1: linear guide support single frame, finite element analysis of the design, to ensure adequate clamping force, not up mode.

large opening stroke, central locking, locking force equilibrium, no deformation.

2: System pressure setting screen: Press the pressure button to enter the system pressure setting screen, which is mainly used to set each action pressure parameter. For example, press the right station button to enter the right station system pressure setting screen, and press the left station button to enter the left station system pressure setting screen.

Process time setting screen: Press the time key to enter the process time screen, which is mainly used to set the parameters of each process forming time. For example, if the duplex station presses the right station button, it enters the right station.Press the left button to enter the left station process time setting screen.

System function configuration screen: Press the function key to enter the process time screen, which is mainly used to set the main functions of the system during operation, such as fan cooling in the heating section and post-processing function of the product.

| SPECIFICATION | SLBC-80 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 30 |

| OUPUT(DRY CYCLE) | PC/HR | 600 |

| MACHINE DIMENSION (LxWxH ) | MM | 5300x3000x3500 |

| TOTAL WEIGHT | TON | 11T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 200 |

| PLATEN OPENING STROKE | MM | 350-850 |

| PLATEN SIZE(WxH) | MM | 750x780 |

| MAX MOULD SIZE(WxH) | MM | 600x1000 |

| MOLD THICKNESS | MM | 360-500 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 80 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 120 |

| BARREL HEATING POWER | KW | 16 |

| NUMBER OF HEATING ZONE | ZONE | 4 |

| EXTRUDER MOTOR RATED POWER | KW | 30 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 4 |

| POWER OF DIE HEATING | KW | 15 |

| MAX DIE-PIN DIAMETER | MM | 250 |

| POWER | ||

| MAX DRIVE POWER | KW | 42 |

| TOTAL POWER | KW | 82 |

| FAN POWER OF SCREW | KW | 3.2 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 32 |

| ACCUMULATOR CAPACITY | L | 6 |