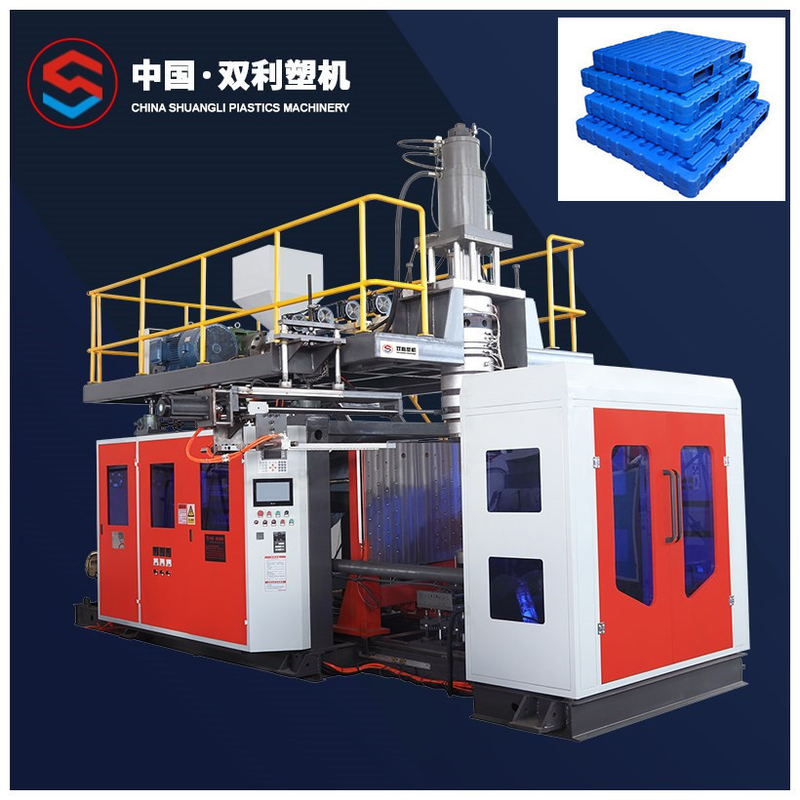

Accumulator Type Single Station 1 Die Head Plastic Blow Molding Machine For Big Size Plastic Pallet or Tray

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity160L

-

ProductBig Size Plastic Pallet Or Tray

-

TypeAccumulator Type

-

StationSingle

-

SpeedHigh Speed

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-120

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Accumulator Type Single Station 1 Die Head Plastic Blow Molding Machine For Big Size Plastic Pallet or Tray

Accumulator Type Single Station 1 Die Head Plastic Blow Molding Machine For Big Size Plastic Pallet or Tray

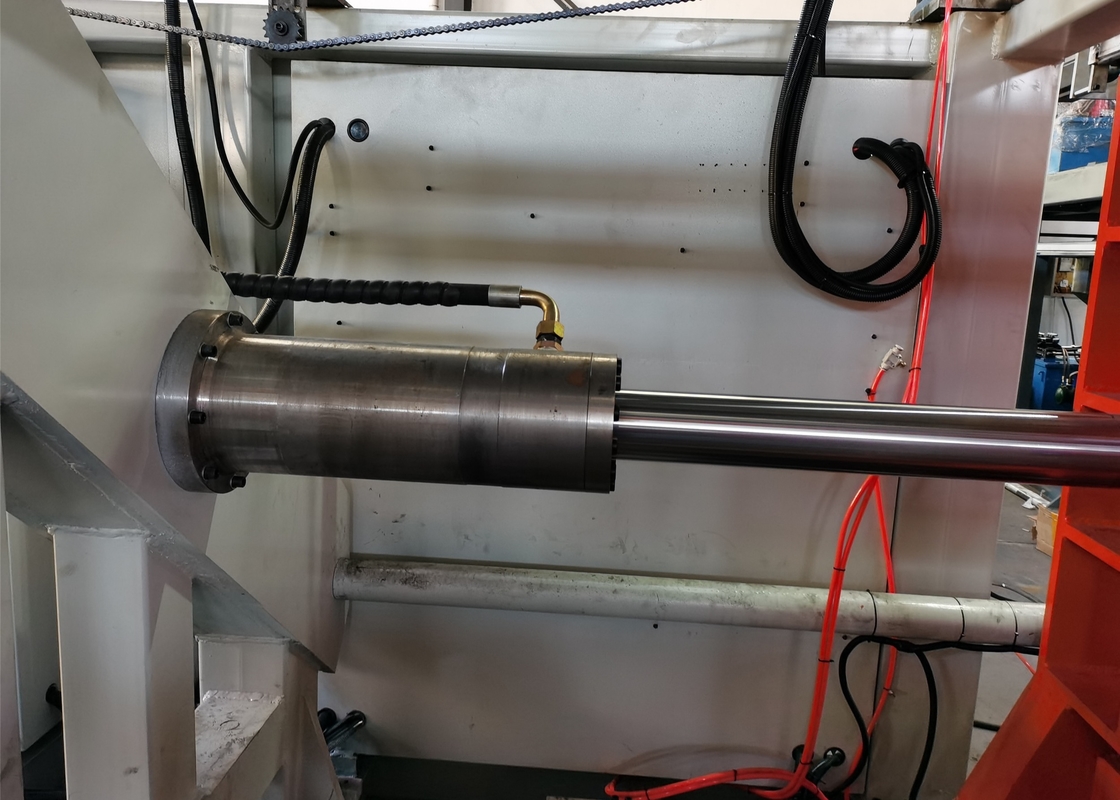

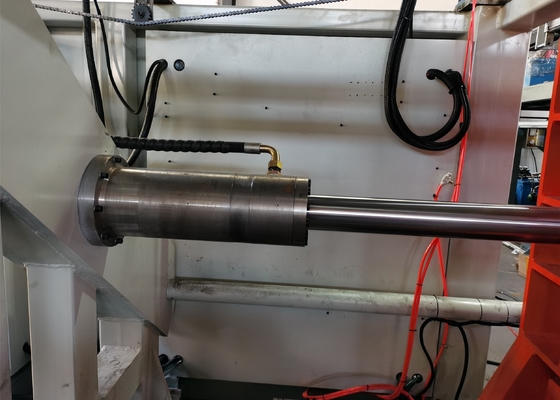

The plasticizing system mainly consists of: twisted material frequency conversion motor, gear reducer, barrel and screw, cast aluminum heater,

cooling fan, fan seat, hopper, die, die lifting device, platform, V-belt pulley, V belt . Its function is to properly heat, extrude, shear, mix and

plasticize the plastic material and then feed it into the extrusion die to form a glue tube . When the system is working, the barrel is heated at a

high temperature! Please pay attention to safety! Prevent burns!

Accumulator Type

SLBC series: (German model)

1: linear guide support single frame, finite element analysis of the design, to ensure adequate clamping force, not up mode.

2: large opening stroke, central locking, locking force equilibrium, no deformation.With Synchronous Mold Clamping Frame Gear Device.

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 300 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x4200x6200 |

| TOTAL WEIGHT | TON | 22T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 800 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 120 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 280 |

| BARREL HEATING POWER | KW | 42 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 90 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 38 |

| MAX DIE-PIN DIAMETER | MM | 500 |

| POWER | ||

| MAX DRIVE POWER | KW | 125 |

| TOTAL POWER | KW | 180 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 72 |

| ACCUMULATOR CAPACITY | L | 30 |

![]()