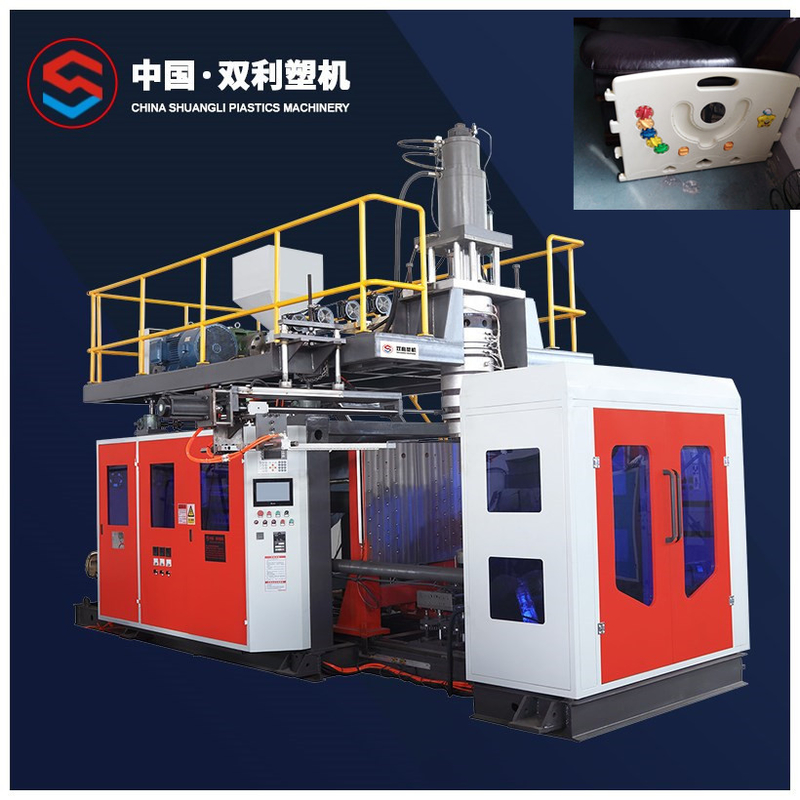

Single Station HDPE Blow Moulding Machine Bottle Blowing Machine

-

High Light

360 bph hdpe bottle blowing machines

,SHUANGLI 360 bph hdpe bottle blowing machines

,SHUANGLI 360 bph hdpe bottle blowing machine

-

MaterialPE,PP,EVA,ABS,PS

-

Max Capacity160L

-

ProductPlastic Kid Bed

-

Clamping TypeTie Bar C Type

-

StationSingle Station

-

Die Head1 Head

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC-110

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Single Station HDPE Blow Moulding Machine Bottle Blowing Machine

1 Die Head Accmulator Type Single Station Plastic Blow Molding Machine For Plastic Kid Bed

1.the whole system is equipped with safety protection grating, to ensure the safety of the production process withoutacciden. And equipped with imported hydraulic, pneumatic and electrical parts of famous brand, it has stable equipment performance and simple handling.large opening stroke, central locking, locking force equilibrium, no deformation.

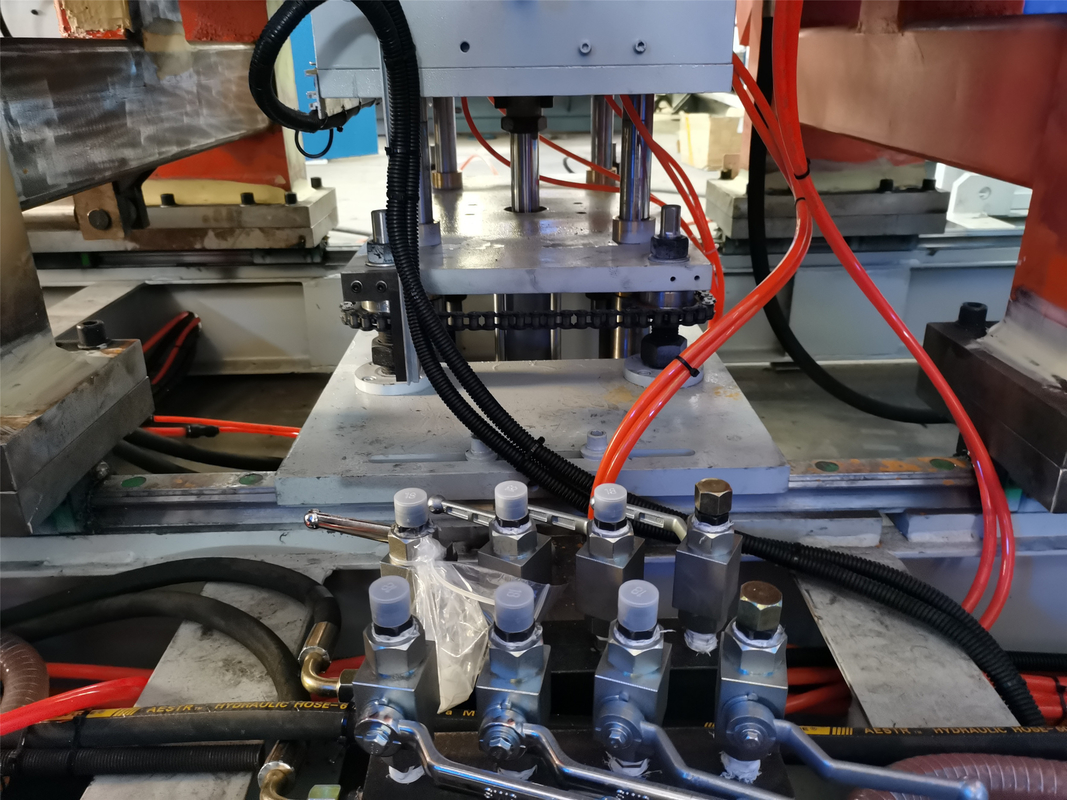

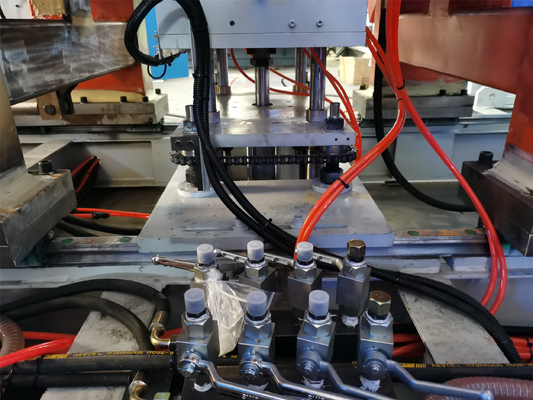

2.An oil mister is used to ensure that the air contains an appropriate amount of lubricant. The oil mister is lubricated with ISO-VG32 turbine oil. There is an oil adjustment screw on the oil to adjust the oil volume, and adjust the drip speed to about 5 drops/min. Leakage in a pneumatic system not only increases the energy consumption, but also causes a drop in the supply pressure, which can also cause the pneumatic components to malfunction. Therefore, it is found that the leak should be handled in time.

| SPECIFICATION | SLBC-110 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 360 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x3600x5800 |

| TOTAL WEIGHT | TON | 20T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 680 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 110 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 220 |

| BARREL HEATING POWER | KW | 36 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 75 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 35 |

| MAX DIE-PIN DIAMETER | MM | 550 |

| POWER | ||

| MAX DRIVE POWER | KW | 120 |

| TOTAL POWER | KW | 130 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 56 |

| ACCUMULATOR CAPACITY | L | 20 |