Single Head Extrusion Blow Moulding Machine For Plastic Chair Base High Speed

-

High Light

Single Head Extrusion Blow Moulding Machine

,High Speed Extrusion Blow Moulding Machine

,160L Extrusion Blow Moulding Machine

-

MaterialPE,PP,,ABS,PS

-

Max Capacity50L-100L-160L

-

StationSingle Station

-

ProductPlastic Chair

-

Machine TypeTie Bar Type-Accumulator

-

Die HeadOne

-

Place of OriginCHINA

-

Brand NameSHUANGLI

-

CertificationISO, CE

-

Model NumberSLBC

-

Minimum Order Quantity1 SET

-

PricePrice negotiation.

-

Packaging DetailsStandard export package

-

Delivery Time20 woking day

-

Payment TermsL/C, T/T

-

Supply Ability100 Set per month

Single Head Extrusion Blow Moulding Machine For Plastic Chair Base High Speed

High Speed Single Head Extrusion Blow Moulding Machine For Plastic Chair Base

SLBC series: (German model)

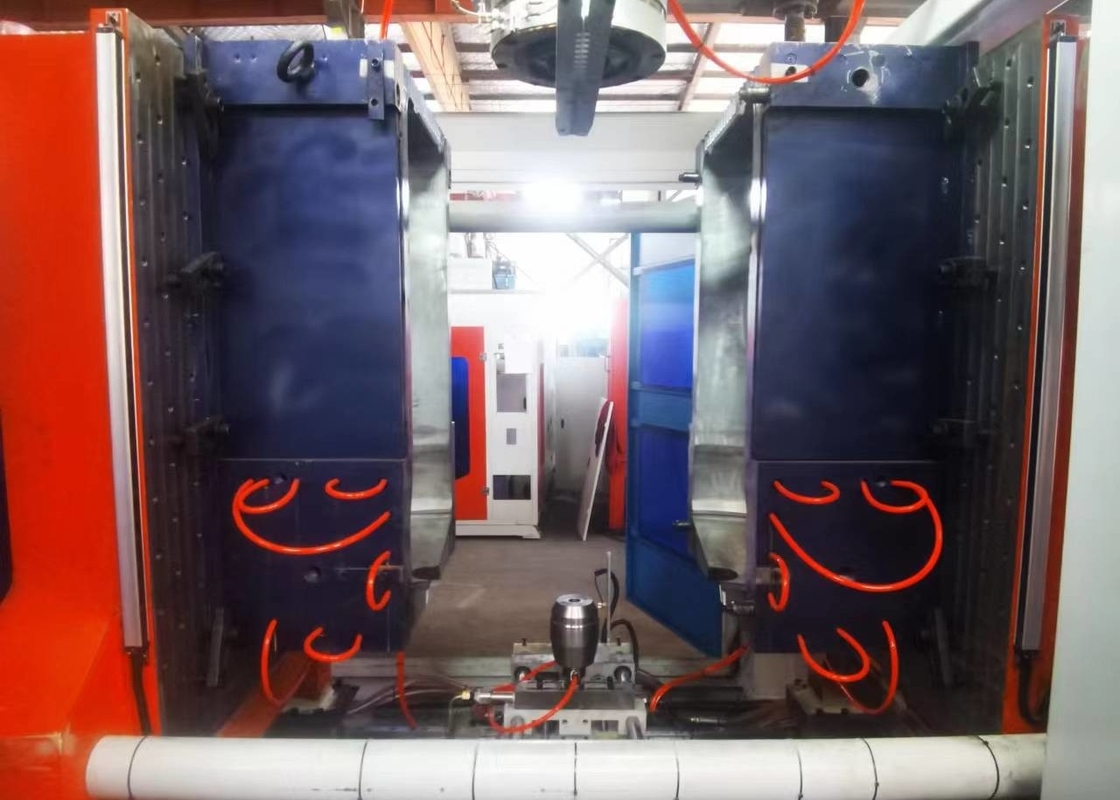

1:Fully Automatic Blow Moulding Machine, large opening stroke, central locking, locking force equilibrium, no deformation. All parts of the machine is made by advanced numerical control equipment with high precision.

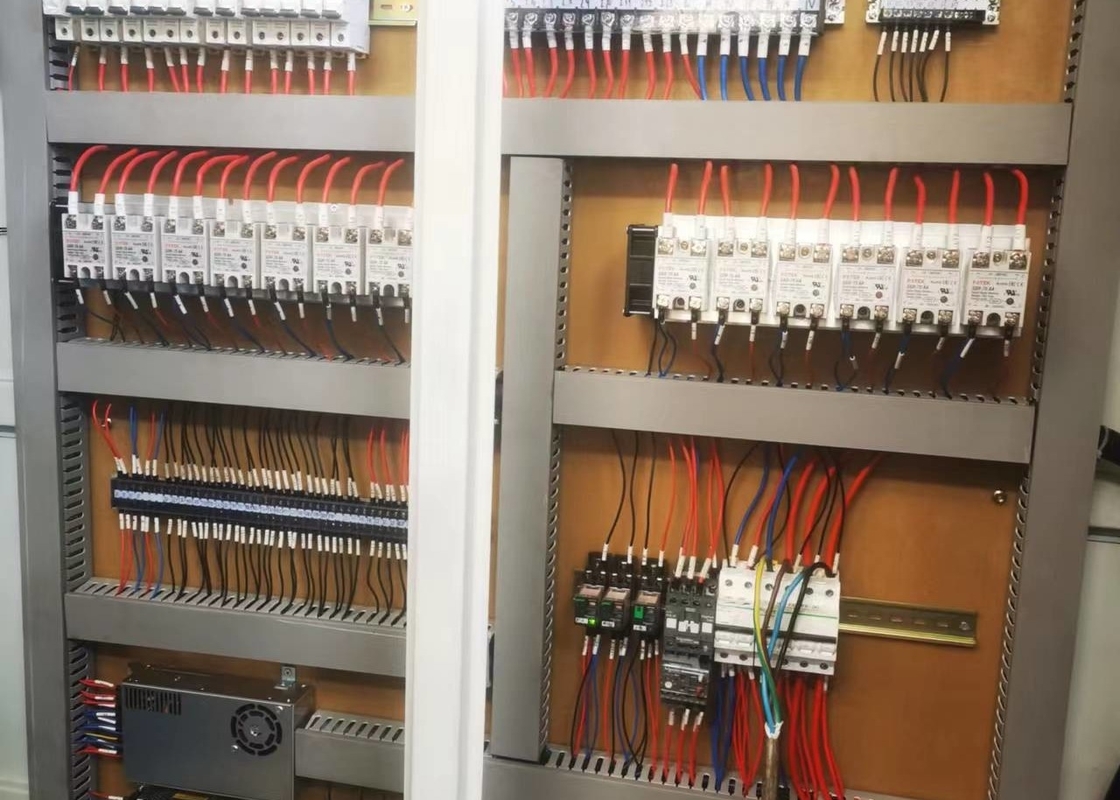

2:Fully Automatic Blow Moulding Machine, The electronic control system consists of operation panel, touch display screen, temperature control module, PLC programmable controller, analog quantity, proportional board, contactor, regulated power supply, automatic air switch, intermediate relay, twisted material inverter, proximity switch, stroke Switch, cutter transformer, twisting motor, oil pump motor and so on.

blowing device

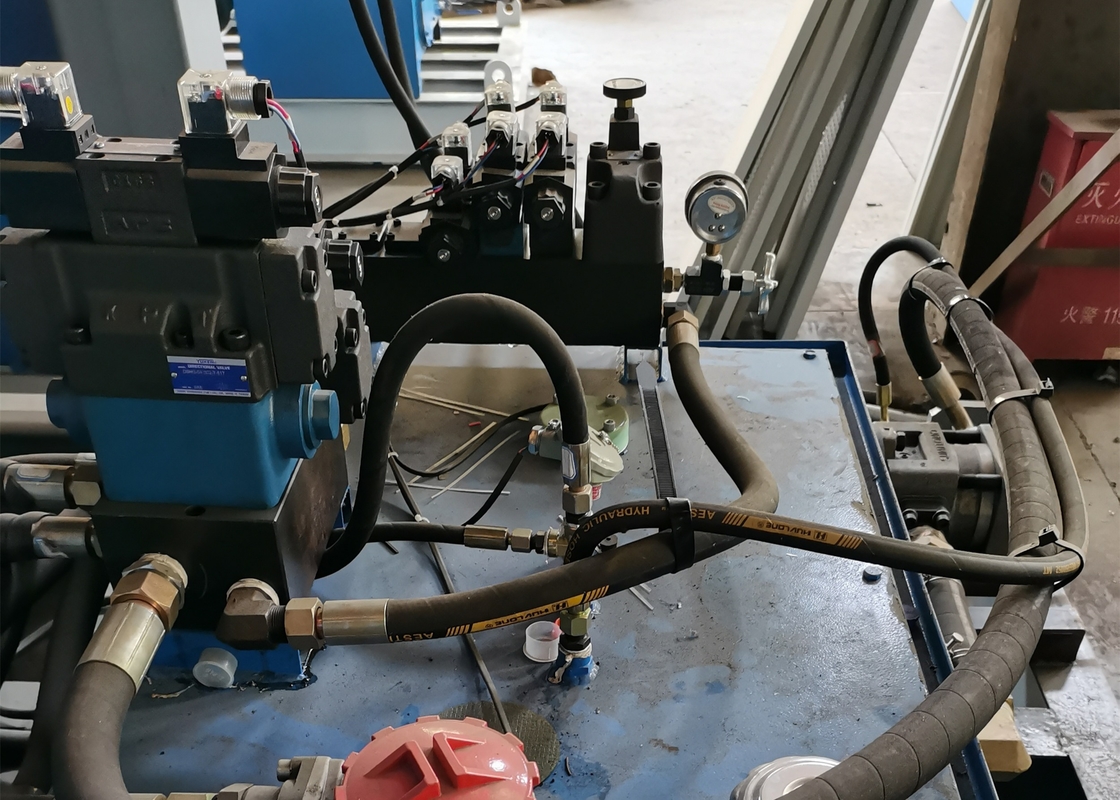

Compressed air usually contains impurities such as water, oil, and dust. Moisture can corrode pipes, valves, cylinders, etc. The oil will deteriorate the sealing material. Dust entering the valve body will cause the spool to malfunction. Therefore, the pneumatic system is equipped with a filter pressure reducing valve. As long as the filter of the filter pressure reducing valve works normally, it can ensure the supply of clean compressed air, that is, the liquid accumulated in the filter is often discharged. The filter uses a semi-automatic draining device that automatically drains the liquid as soon as the air supply is turned off. The operator should always check the filter of the filter regulator and find that the liquid in the filter is drained immediately as it approaches the tick mark. Most pneumatic actuators and control components require proper lubrication

| SPECIFICATION | SLBC-120 | |

| MATERIAL | PE,PP,EVA,ABS,PS | |

| MAX CONTAINER CAPACITY | L | 160 |

| OUPUT(DRY CYCLE) | PC/HR | 300 |

| MACHINE DIMENSION (LxWxH ) | MM | 7500x4200x6200 |

| TOTAL WEIGHT | TON | 22T |

| CLAMPING UNIT | ||

| CLAMPING FORCE | KN | 800 |

| PLATEN OPENING STROKE | MM | 600-1400 |

| PLATEN SIZE(WxH) | MM | 1400x1600 |

| MAX MOULD SIZE(WxH) | MM | 1200x1900 |

| MOLD THICKNESS | MM | 610-880 |

| EXTRUDER UNIT | ||

| SCREW DIAMETER | MM | 120 |

| SCREW L/D RATIO | L/D | 25 |

| MELTING CAPACITY | KG/HR | 280 |

| BARREL HEATING POWER | KW | 42 |

| NUMBER OF HEATING ZONE | ZONE | 6 |

| EXTRUDER MOTOR RATED POWER | KW | 90 |

| DIE HEAD | ||

| NUMBER OF DIE HEATING ZONE | ZONE | 5 |

| POWER OF DIE HEATING | KW | 38 |

| MAX DIE-PIN DIAMETER | MM | 500 |

| POWER | ||

| MAX DRIVE POWER | KW | 125 |

| TOTAL POWER | KW | 180 |

| FAN POWER OF SCREW | KW | 4.8 |

| AIR PRESSURE | MPA | 0.8-1.2 |

| AIR CONSUMPTION | M3/MIN | 0.8 |

| AVERAGE ENERGY CONSUMPTION | KW | 72 |

| ACCUMULATOR CAPACITY | L | 30 |

![]()